Technologies

60 years of technology mastery

Our R&D department commits its energy to stretch the limits of the technology. While expressing the results of that activity into solutions that remain open for both the installers as well as the users.

Since 60 years, BEA has been achieving a reputed authority in technologies applied to the domain of detection and receives worldwide recognition as an expert by its peers.

LASER

LASER technology works according to the principle of time of flight. The sensor sends an intense light impulse in a defined direction and measures the time until the signal returns. As the speed of light is a constant value (approximately 300,000 km/s), this time is directly proportional to the distance between the sensor and the first object encountered by the light impulse.

As a result, and by sending multiple beams in multiple directions (2D or 3D), the sensor is capable of knowing the exact position of any object in its detection area at any given time.

By analyzing this information over a very short period of time, it is easy to determine the shape, speed, and direction of any object.

LASER technology is the most precise and accurate method used in BEA products and delivers the highest ever level of safety.

-

LZR®-FLATSCAN 3D SWLearn more

LZR®-FLATSCAN 3D SWLearn more -

LZR®-VISIOSCAN RDLearn more

LZR®-VISIOSCAN RDLearn more -

LZR®-WIDESCANLearn more

LZR®-WIDESCANLearn more

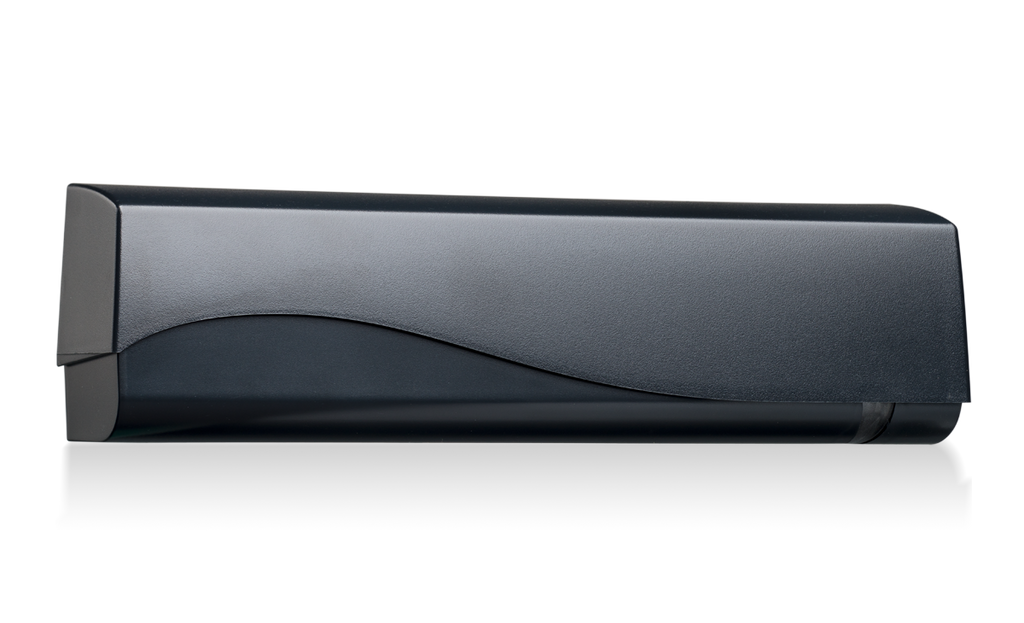

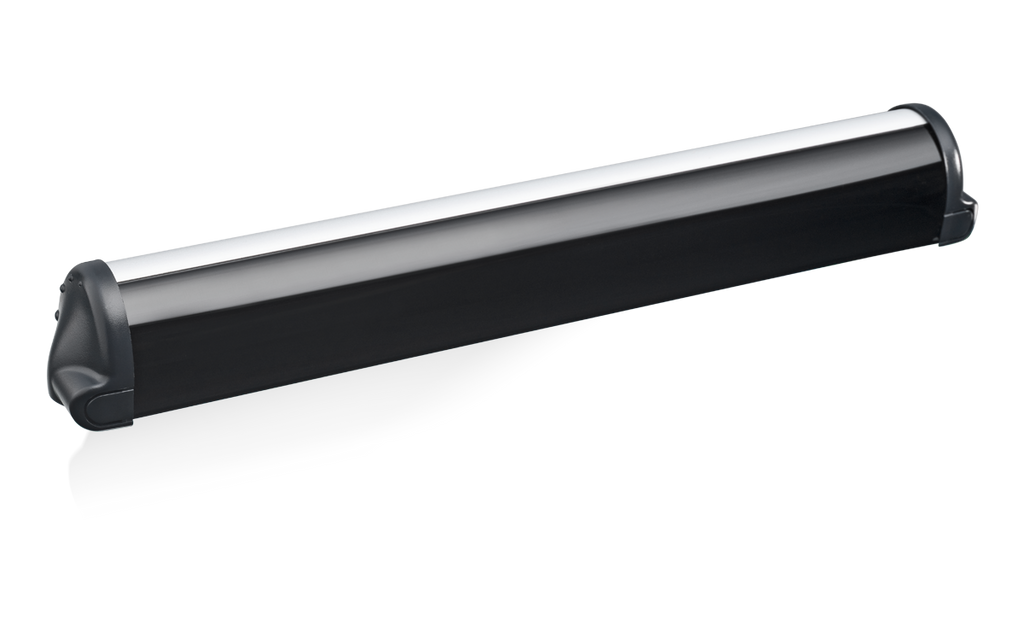

RADAR

Radar technology, also called microwave technology, is based on the Doppler Effect:

the radar sensor continuously emits microwaves with a certain frequency in a defined area. These microwaves are reflected back to the sensor by all of the objects present in its environment.

If the objects in the area do not move, the microwaves come back to the sensor with the same frequency as the initial one. Once a movement occurs in the detection field, the microwaves come back to the sensor with a different frequency and this results in a detection.

Furthermore, this technology can distinguish between an approaching movement (higher frequency) and a departing movement (lower frequency), allowing the sensor to only open the door for an approaching target. This function, known as ‘direction sensing/unidirectionality’, reduces door opening cycles and generates energy savings.

Over the years, radar technology has become the perfect choice for detecting moving objects in a well-defined area.

-

FALCONLearn more

FALCONLearn more -

MAGIC SWITCH CHROMALearn more

MAGIC SWITCH CHROMALearn more

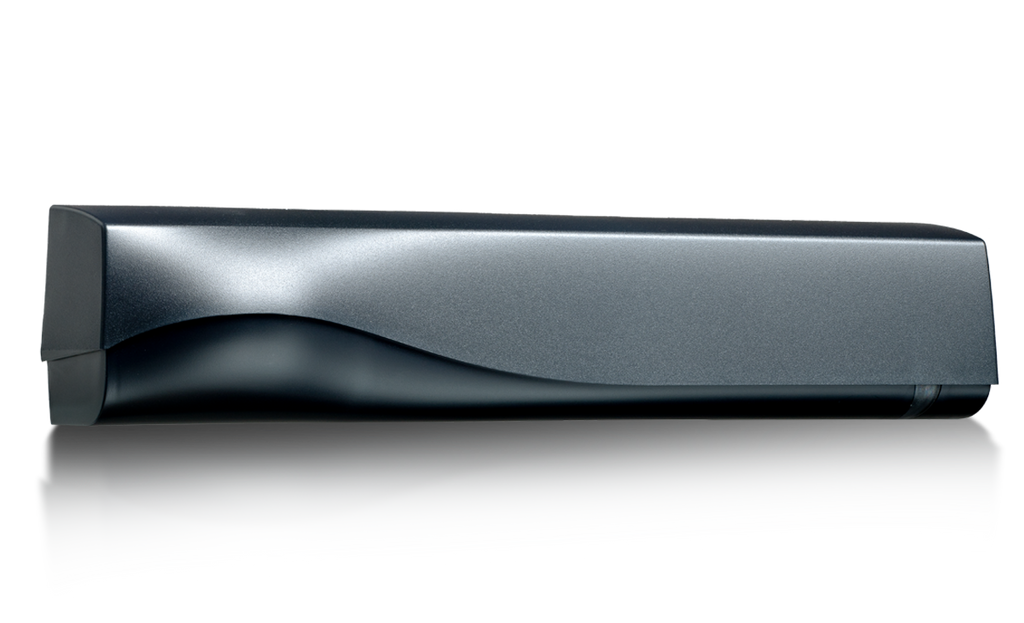

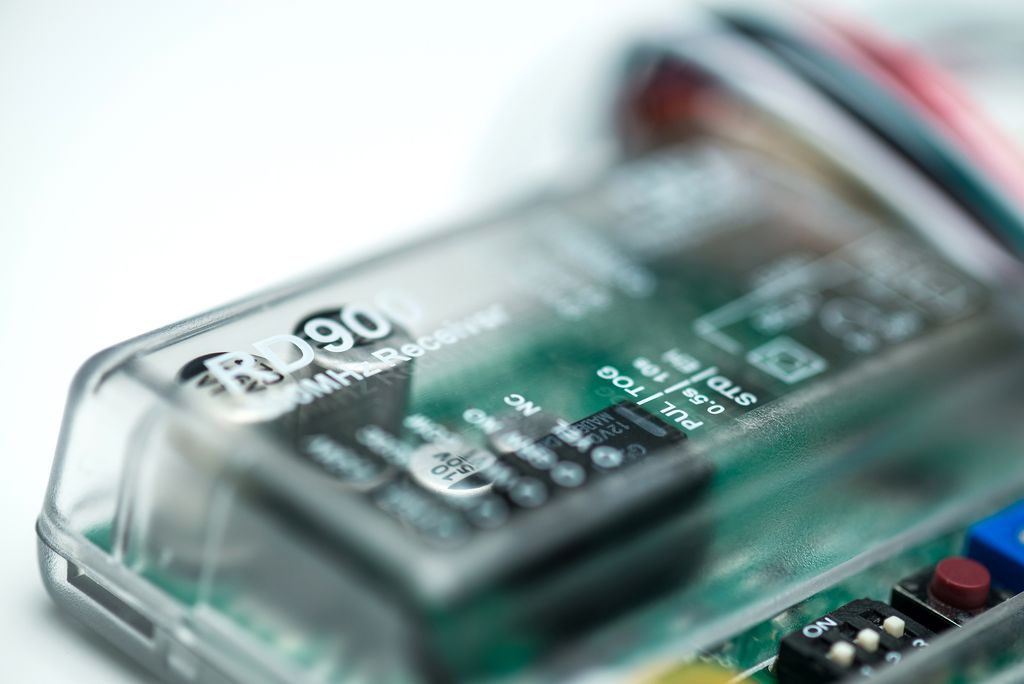

RADAR - Artek inside

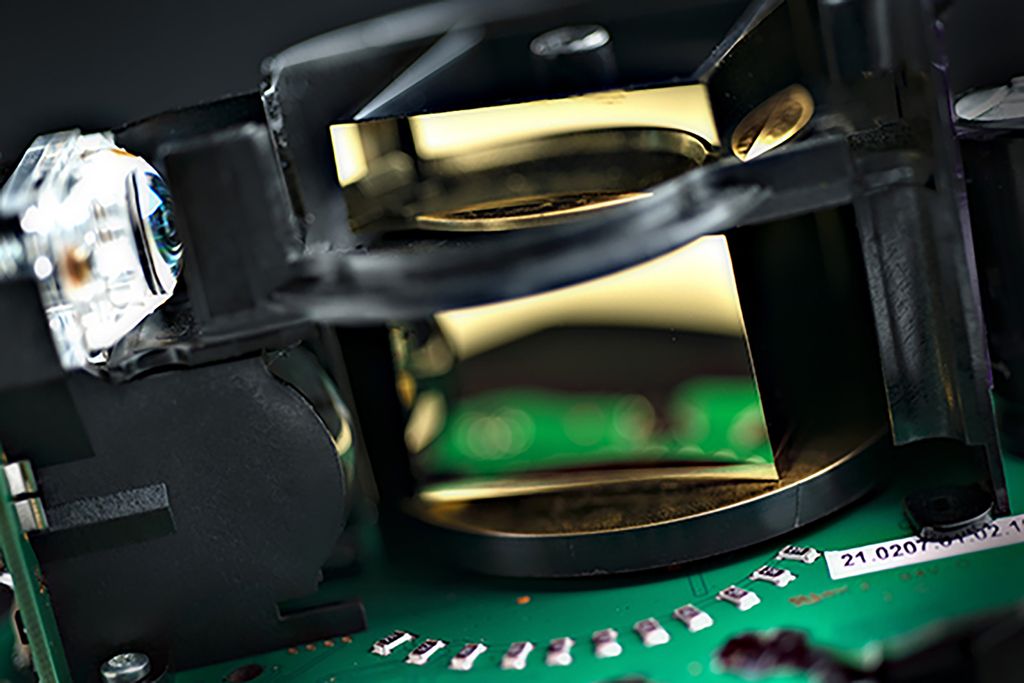

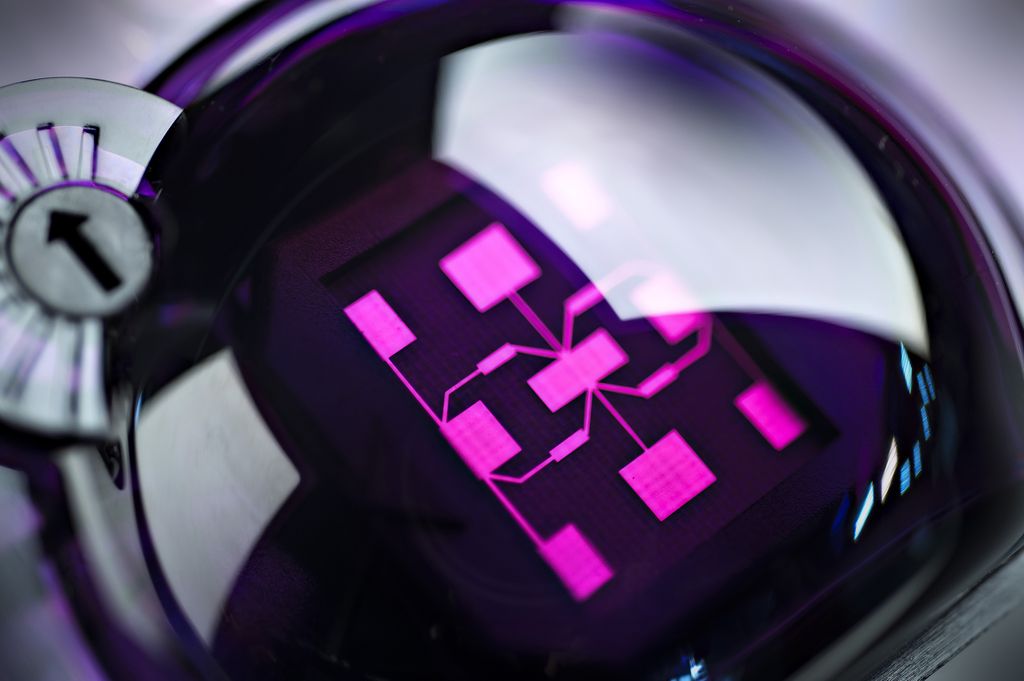

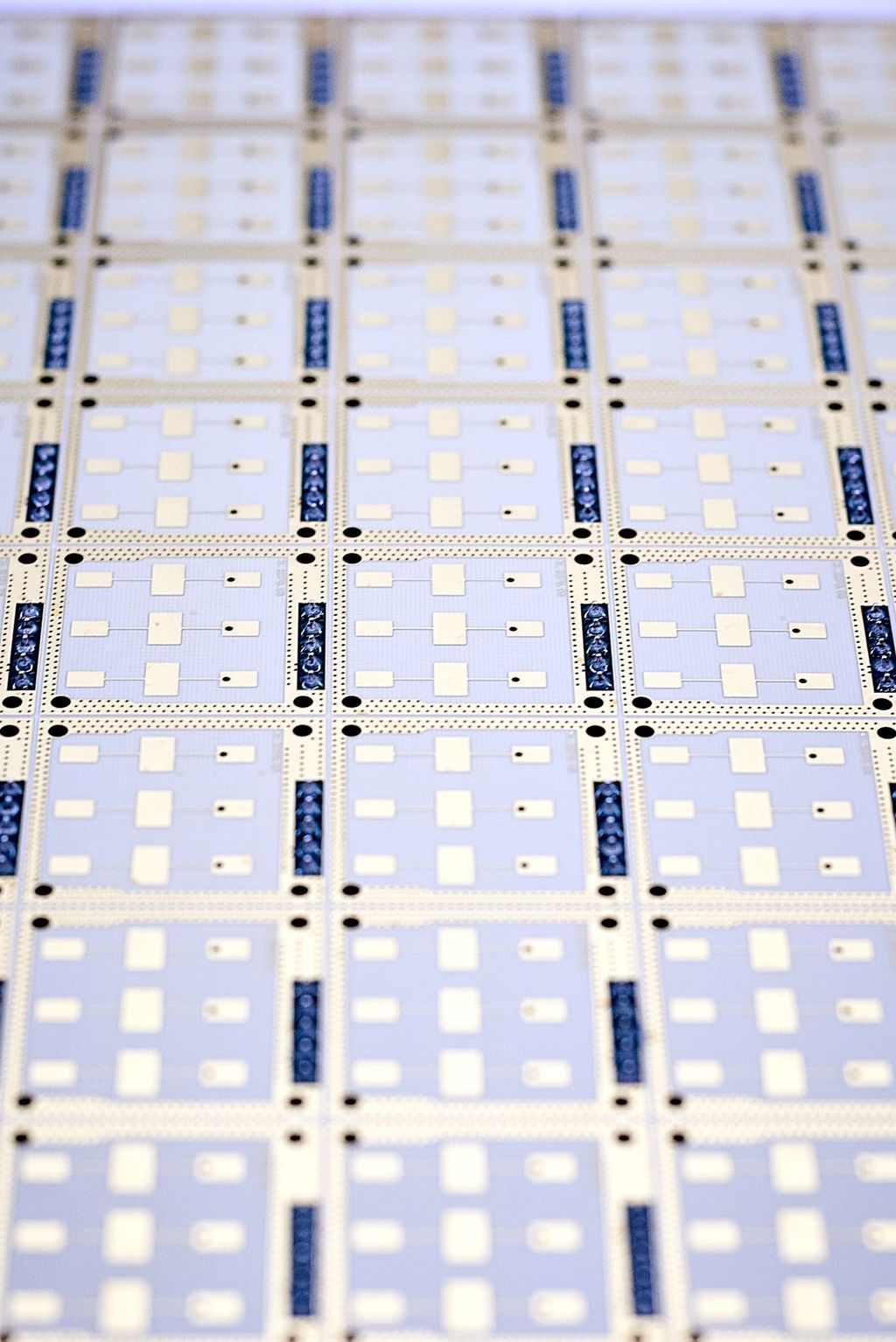

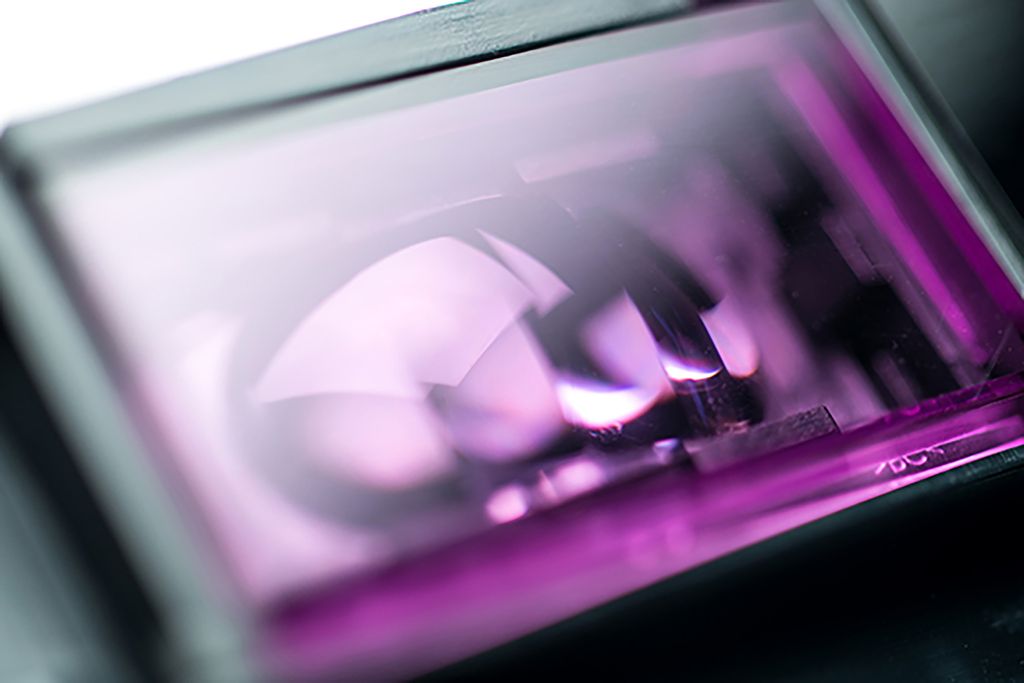

BEA started implementing the radar technology 1972 using the horn antenna. In 1996 the EAGLE sensor revolutionised motion detection with its more compact planar antenna. And after 50 years of experience with radar technology, it is now time to go digital with Artek inside.

Many hours of research, development and testing have been invested to create and develop the Artek technology. Thanks to the know-how of our engineers, this active digital antenna takes motion detection to the next level. The robust and sustainable design, cutting edge electronics and software allow for precision, reliability, and more flexibility, setting the new standard for motion detection.

On our in-house production line, state-of-the-art equipment and experienced personnel work together to produce the Artek electronics. This way, we control the whole process from start to finish, which implicates a great sense of mastery and independence. Components are printed on circuit boards with quality checks by camera and the human eye. Less waste, logistics and time delay also contribute to a smooth work process and above all, the well-being of our planet.

ARTEK inside, made by BEA with passion.

-

EAGLE ARTEKLearn more

EAGLE ARTEKLearn more -

IXIO-DLearn more

IXIO-DLearn more

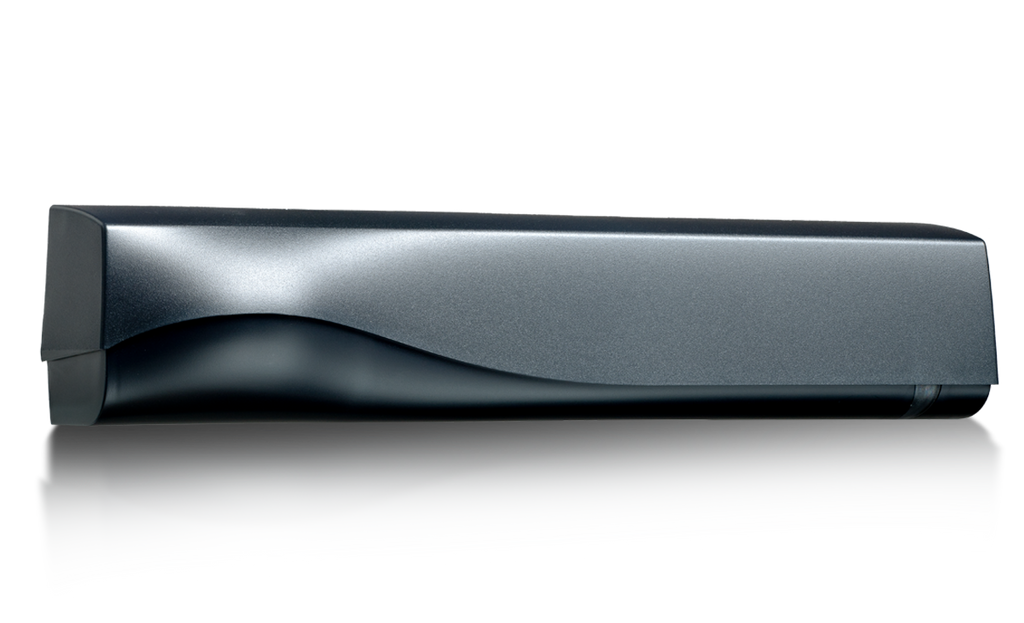

ACTIVE INFRARED with background analysis

An active infrared sensor is, by definition, a sensor that emits infrared light in a well-defined area and analyzes the reflections that come back.

Background analysis always works with a background (e.g. a sensor shines infrared light on the floor). In this case, the sensor lights up one or more areas and analyzes the energy that returns. Detection is triggered if there is any significant difference when compared to the original picture.

This technology, which is highly sensitive, is the best method for detecting static objects close to a door. It is also often combined with a radar sensor to provide the best option for opening doors (radar) and safeguarding objects (infrared) using a single device.

-

IXIO-SLearn more

IXIO-SLearn more -

MILANLearn more

MILANLearn more -

RS-15Learn more

RS-15Learn more

ACTIVE INFRARED with background suppression

An active infrared sensor is, by definition, a sensor that emits infrared light in a well-defined area and analyzes the reflections that come back.

Background suppression works on the principle of ‘triangulation, in which the sensor calculates the distance to an object by taking into account the distance between the emitter and receiver. The emission angle is already known and the reflection angle becomes the key element as the distance to the object can be calculated according to the position of the reflected spot on the receiver side (a triangle can be drawn when you know one distance and two angles).

This technology, which requires a small uncovered zone on the floor, facilitates the detection of static objects without being influenced by the reflectivity of the background. It is therefore mostly used when the background is likely to change (e.g. sensor is fixed on a moving door panel).

-

4SAFELearn more

4SAFELearn more -

1SAFELearn more

1SAFELearn more

FMCW - MoWa inside

FMCW (Frequency-Modulated Continuous Wave) technology operates by continuously emitting a frequency-modulated signal. The sensor sends out a wave that gradually changes in frequency over time. When this wave reflects off an object and returns to the sensor, its frequency is compared to the emitted wave. The difference between these frequencies, known as the beat frequency, is directly proportional to the distance between the sensor and the object.

FMCW technology provides highly precise distance measurements with continuous data updates, which enables the sensor to detect instantaneously both stationary and moving objects.

By continuously analysing changes in frequency over time, FMCW technology can also determine an object’s velocity and direction, making it highly effective in applications requiring real-time tracking and precise positioning.

MoWa inside, which is based on FMCW technology, measures the distance and speed of objects in the detection field. By transmitting a modulated wave and measuring the frequency shift of the reflected signal, it can detect and classify people and all types of vehicles, whether moving or standing still.

-

EVOLOOPLearn more

EVOLOOPLearn more

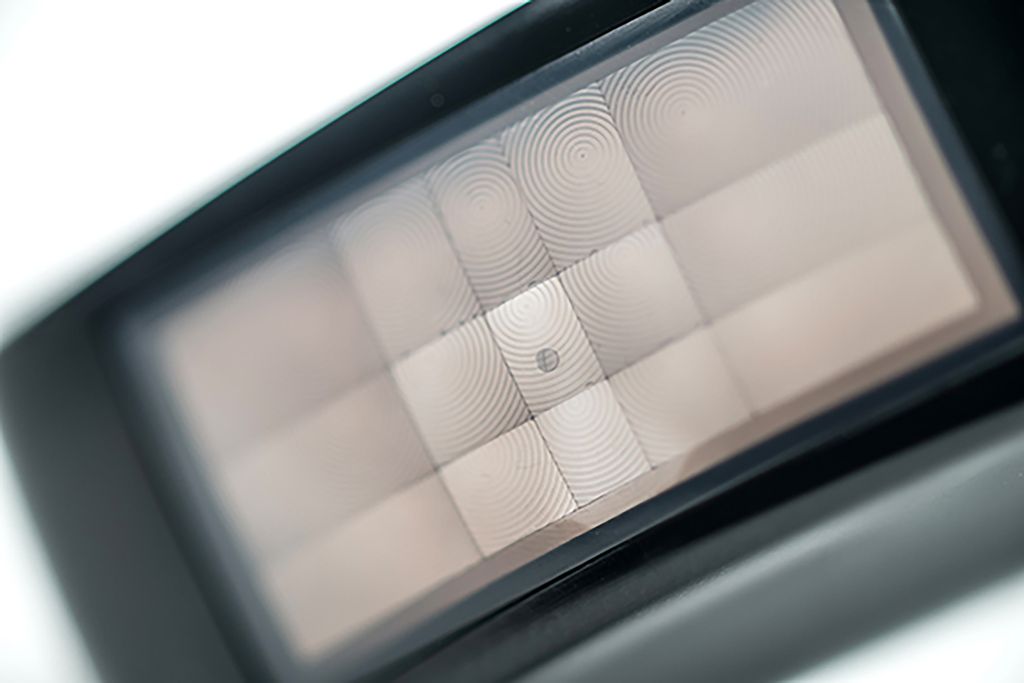

PASSIVE INFRARED

A passive infrared sensor is a sensor that measures the infrared light radiating from objects in its field of view.

Motion or presence is detected when an infrared source with one temperature, such as a human being, passes in front of an infrared source with another temperature, such as the normal environment.

Passive infrared sensors have adjustable detection areas and are rather insensitive to ‘cold’, static objects.

Over the years, passive infrared technology has been increasingly replaced by radar and active infrared technologies to increase detection reliability. Nevertheless, there are still some applications for which passive infrared sensors are well suited.

-

FLYLearn more

FLYLearn more

PIEZO

Piezo technology, also known as piezoelectric, is the process of converting mechanical pressure (pushing a button) into electrical energy. A Piezo switch is paired with a field effect transistor (FET) that, when pushed, allows current to flow through the FET. The change of the current triggers an “on” signal that can be used for automatic door activation. When the button is released, the current shuts off. Piezo switches have no moving parts and therefore have a very long lifespan. They are commonly used for the knowing act activation of automatic doors, gates and other access points.

-

PUSH PLATESLearn more

PUSH PLATESLearn more

CAPACITIVE

Capacitive technology detects close-range electrically charged objects. A small voltage is applied to a conductive surface, resulting in a uniform electrostatic detection field. When a conductor, such as the human hand, enters this field detection occurs. Capacitive sensors are used for activation via presence.

-

PUSH PLATESLearn more

PUSH PLATESLearn more -

PUSH PLATES SLLearn more

PUSH PLATES SLLearn more

RADIO CONTROL FREQUENCY

Wireless technology uses transmitters and receivers operating on specific radio frequencies. The transmitter applies a radio frequency alternating current to an antenna, which then radiates radio waves. The receiver receives the transmitted frequency and converts the information into a usable form. Radio transmitters and receivers are used for activation.

-

PUSH PLATESLearn more

PUSH PLATESLearn more -

PUSH PLATES SLLearn more

PUSH PLATES SLLearn more -

EAS RFLearn more

EAS RFLearn more

VIDEO

Video technology uses optics and light to create pictures and videos. Enhanced definition cameras capture door environment and traffic usage in full color and high quality. Cameras are used within sensors to increase security and decrease liability.

-

IXIO-DLearn more

IXIO-DLearn more

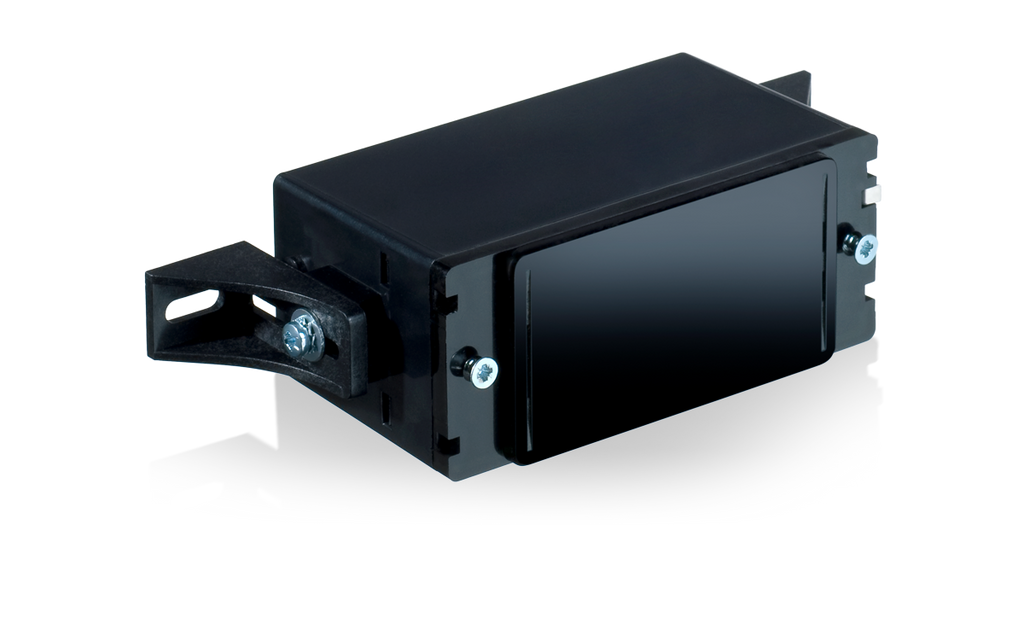

INDUCTION LOOPS

Induction loops are based on the following principle:

An electrically conductive loop is installed in the pavement (multiple wires) and connected to a nearby electronic sensor. This sensor transmits energy into the wires and a magnetic field is generated. When a metallic object (vehicle) passes over the loop, the properties of the magnetic field will change (modification of the inductance). This modification is detected by the sensor and the outputs are activated.

The main advantage of this technology is a perfect filtering between metallic objects (e.g. vehicles) and non-metallic objects (e.g. people). Nevertheless, the installation and maintenance of this technology require a lot of effort (loops in the pavement) and an increasing number of alternatives (LASER or AIR based products) are being used by the market.

-

MATRIXLearn more

MATRIXLearn more

See all our segments

-

-

Doors & Windows

-

Guidance & Access Control

-

-

-

Doors

-

Gates & Barriers

-

-

-

Autonomous Robots

-

Traffic & Transport Solution

-

Asset Protection

-