Developed over the last several decades, automatic doors are now widely used – from airports, shopping centres, office buildings to hotels and have essentially become an integral part of different industries. Automatic doors not only offer added convenience, improved safety, a seamless, hands-free entry experience to pedestrians but also bring along various benefits such as energy saving and hygiene. However, just like cars and elevators, if not properly designed, installed, maintained or with the appropriate sensors, there are still chances of accidents. According to the data from the U.S. Consumer Product Safety Commission (CPSC), each year in the U.S over 2,000 people, including 800 children, are treated in hospital emergency rooms for injuries to the head, neck, arm, or hand. Most of the injuries are due to the malfunction of the doors or inadequate use of appropriate sensors.

In order to reduce or even eliminate these potential risks and protect the safety of pedestrians, some countries issued relevant policies requiring automatic doors must be equipped with relevant safety equipment, such as GB/T34616, T/CCMSA 10925 in China, JIS A 4722 in Japan, AS 5007 in Australian, ANSI A 156.10 in U.S. EN16005 is the specification for CEN automatic doors in Europe, which covers safety in the use of power operated pedestrian doorsets used for normal access, in escape routes and as fire resistance and/or smoke control doorsets. All these standards, no matter from which country or region they are, are designed for the safety of automatic doors, with a clear definition of the hazard areas, methods of protection and how to avoid the hazard points/areas. The types of electric pedestrian doors include sliding doors, swing doors, revolving doors, balanced doors and folding doors with horizontal moving doors, and define the hazard areas and methods of protection and avoid the hazard points/areas involved in these door types.

For each type of door, the danger points lie in different aspects. Here in this article we would like to share with you what are the danger points covered in EN16005 for sliding doors and how to avoid and protect the danger points. Hopefully this sharing would be beneficial to the pedestrians to enhance safety awareness to help reduce the chances of injuries; to the architects, like developers, manufacturers, installers, service companies and building owners, more aware of the standard and protection measures, or else who are potentially liable if there is an accident involving a power-operated door; to the specifiers who must also be careful to select suppliers who can provide qualified staff, to ensure that the installer is aware of its responsibilities and the correct settings.

Avoidance of Danger Points and Protection at Danger Points

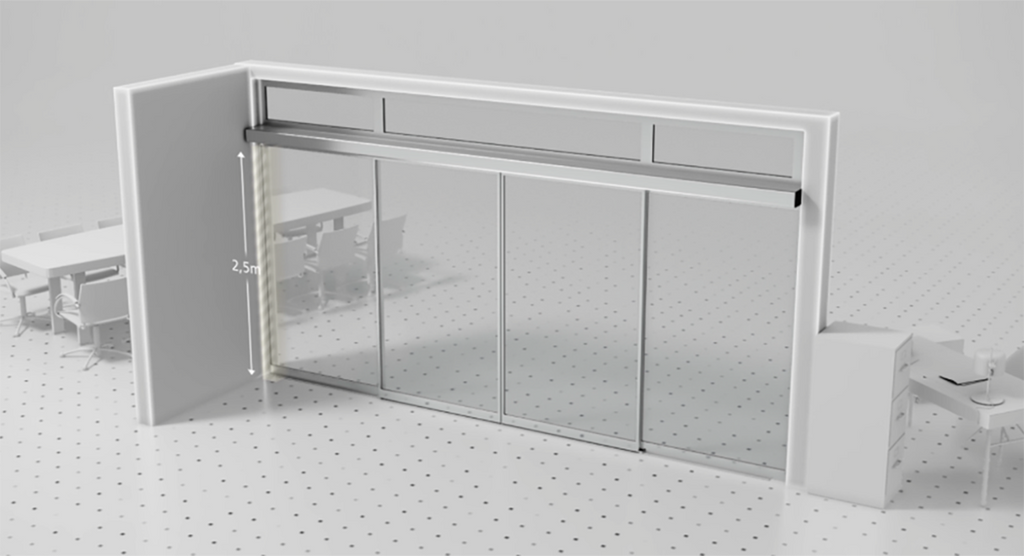

According to the standard, power-operated pedestrian doorsets shall be designed so that hazards due to crushing, shearing, impact and drawing-in during the opening and closing cycles are avoided so that safeguards against such hazards are provided. Danger points shall be safeguarded up to a height of 2.5 m above the floor with the following exception:

- The guide slot in the drive cover or drive arm or closing action at the top of the doorset below the lintel is not regarded as a danger point and a protective device need not be provided at this point as any contact with it requires an intentional action.

- Danger points between the leaf and frame presenting a finger trap hazard can be protected up to only 2m.

Opening of the Automatic Sliding Doors

Safeguards concerning the danger of crushing and impact shall be deemed to have been provided at the danger points during the opening cycle if one of the following requirements is met, considering that when a large proportion of the users are elderly, infirm, disabled persons and young children any contact of the doorset with the user is unacceptable:

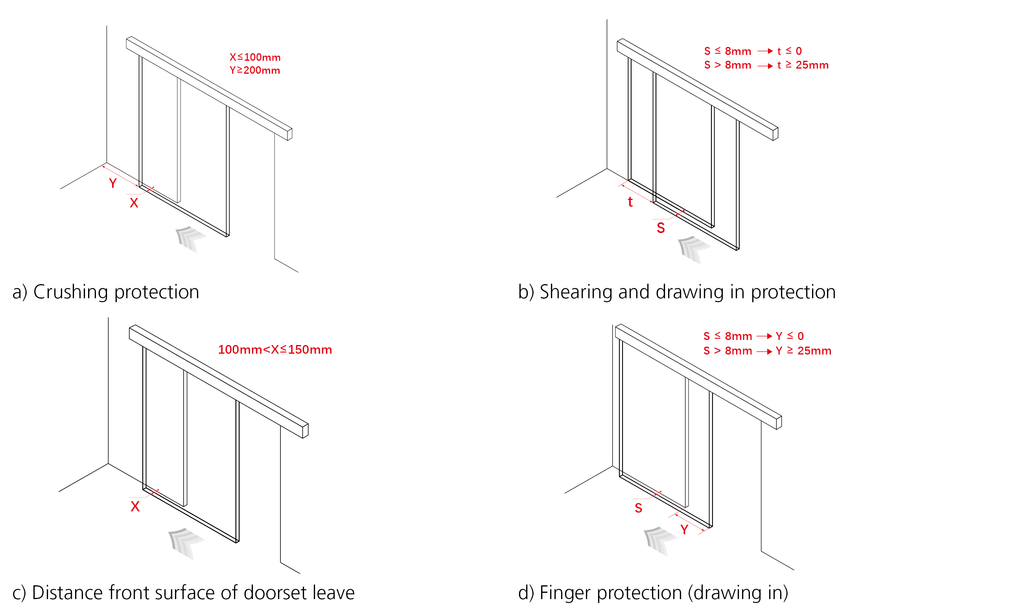

- there is a safety distance (Y) ≥ 200 mm between the secondary closing edge and adjacent parts of the surroundings with regard to the endangered parts of the human body and the leaves move along a plain part and the distance (X) between the front surface of the leave and the fixed side screen is not more than 100 mm (see below Figure a)). In this case, the impact hazard and the hazard concerning crushing of the body are considered to be not relevant. or

- the force of the leaves is limited to the permitted forces specified in 4.6.7.2 and the leaves move along a plain part and the distance (X) between the front surface of the leave and the fixed side screen is more than 100 mm and less or equal to 150 mm (see Figure c), or

- protective devices in accordance with 4.6.8 are provided between the secondary closing edge and adjacent parts of the surroundings, or

- the area of the secondary closing edge is covered by guards in accordance with 4.6.9, positioned at a distance of ≤ 8mm or ≥ 25mm in front of the doorset leaf, or

- the area of the secondary closing edge is covered by barriers in accordance with 4.6.10, positioned in a distance of ≤ 8mm or ≥ 25mm in front of the moving part of the doorset, or;

- the movement fulfils the low energy requirements of 4.6.4.

Safeguards concerning shearing and drawing-in hazards shall be deemed to have been provided at the danger points during the opening cycle if safety distances shown in Figure b) and d) are met.

Closing of the Doorset

Safeguards shall be deemed to have been provided at the danger points during the closing cycle if one of the following requirements is met, considering that when a large proportion of the users are elderly, infirm, disabled persons and young children, any contact of the doorset with the user is to be considered unacceptable:

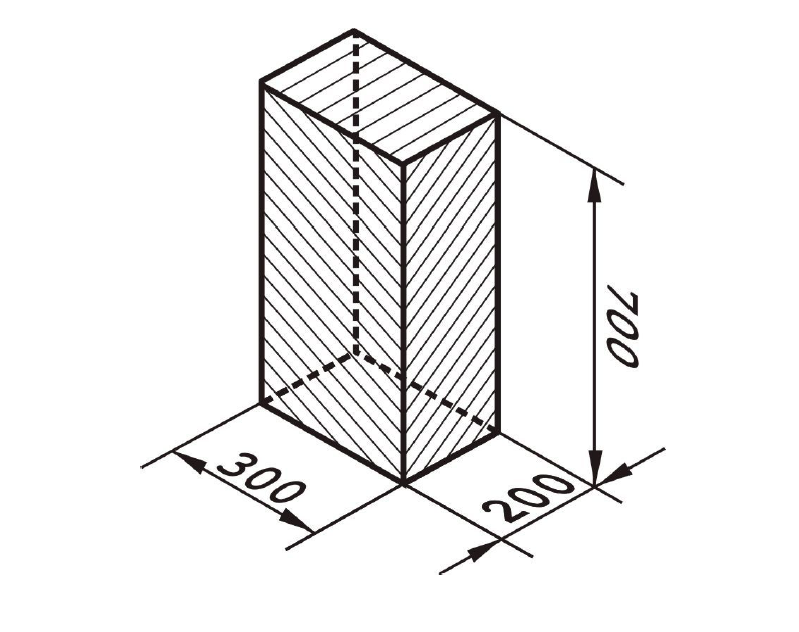

- protective devices in accordance with 4.6.8 are provided at the main closing edge so that in protection area the reference body CA (700x300x200mm) is detected in all positions of the travel area of the doorset leaves, or

- the movement fulfils the low energy requirements of 4.6.4.

Ways to Safeguard Danger Points

- Low energy movement (4.6.4)

- Limitation of leaf forces (4.6.7)

- Electro-sensitive protective equipment (ESPE) and/or pressure sensitive protective equipment (PSPE) (4.6.8)

- Guards (4.6.9)

- Barriers (4.6.10 and 4.6.11)

- Safety distances (4.6.11)

Protective Devices Shall be Designed So That:

- a command preventing hazardous leaf movements shall be given while a protective device is actuated.

- after resetting them a functional check is carried out and normal operation of the doorset is started only if safety functions are in place.

- permissible operating forces shall not be exceeded after a protective device has been actuated.

- ESPE that continuously adapt to environmental changes shall be field adjusted to adapt to any environmental change lasting at least 30s.

Sensor control units and output signal switching devices which can be exposed to outdoor conditions shall be protected to a level of at least IP44 or higher (see EN 60529) in installation. The protective device complies with the requirements of EN 12978.

There are two kinds of environments depending on the risk assessments you made. When a large proportion of the users are elderly, infirm, disabled persons and young children any contact of the doorset with the user is unacceptable.

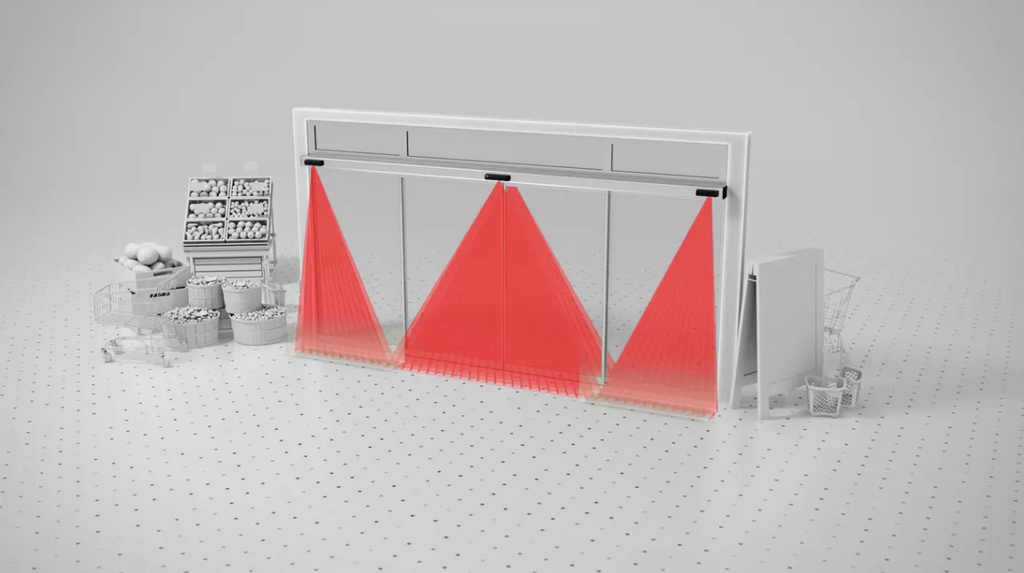

High-Risk Environment

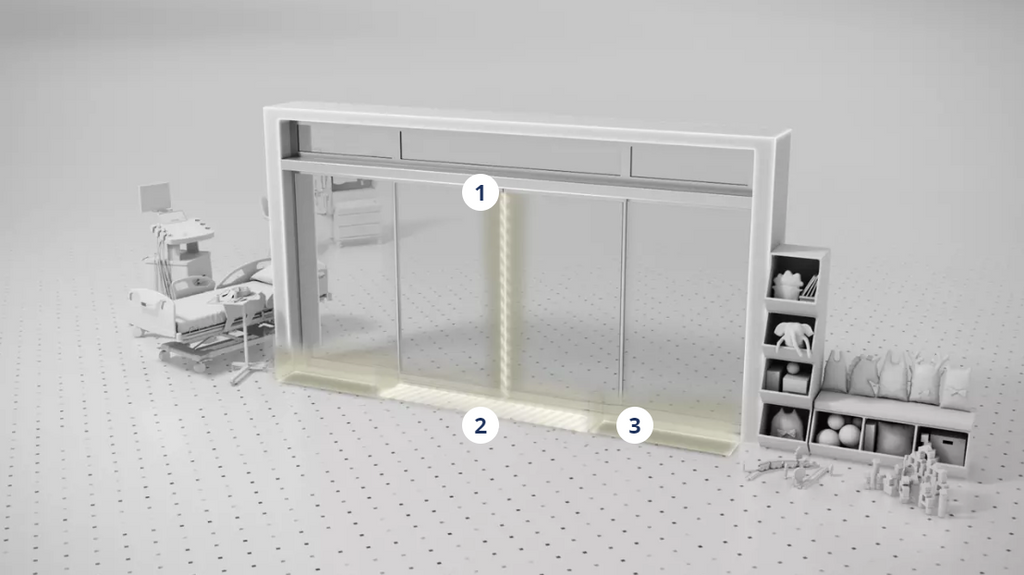

In this environment, there is a large portion of elderly, disabled and young children passing through automatic sliding doors, like in hospitals, schools, supermarkets and airports.

High-Risk Environment Risky Areas

- The main closing edge (When the door closes and the sensor fails to detect the object is still at the door, there is a possibility of crushing the object).

- The door threshold (During the closing, the sensor should be able to detect the object so as to avoid any contact in the process).

- The side screen safety (During the opening, if the sensor fails to detect the object between the side screen and the adjacent walls, there is a possibility of hitting the object).

BEA Offers In High-Risk Environment

The IXIO-D secures the door threshold during closing. Combined with the IXIO-S for the sidescreen safety, it offers a complete solution for sliding doors avoiding all risks.

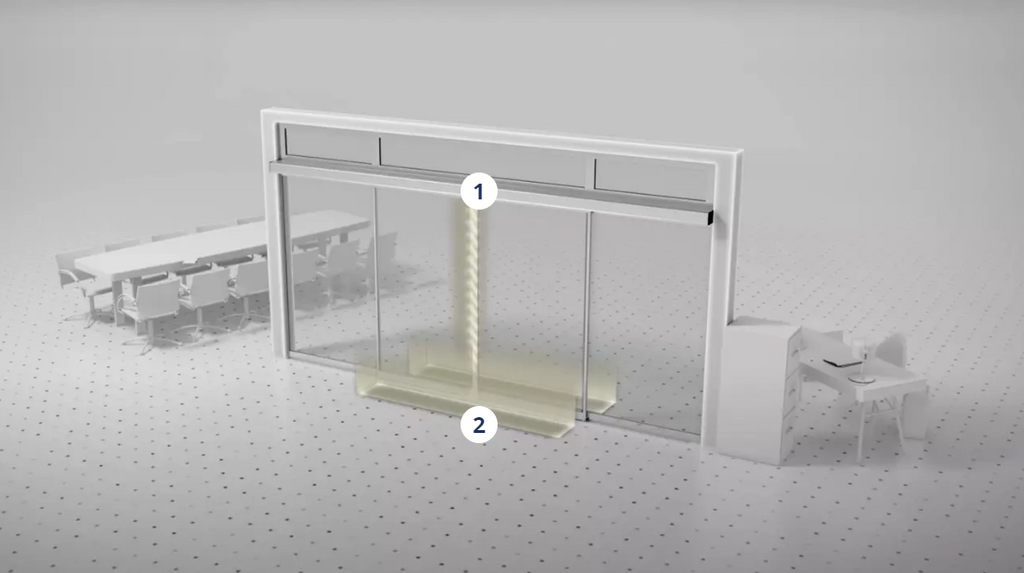

Tolerated-Risk Environment

In this environment, there is a very low proportion of elderly, disabled and young children passing through automatic sliding doors, like in an office building.

Tolerated-Risk Environment Risky Areas

- The main closing edge (When the door closes and the sensor fails to detect the object is still at the door, there is a possibility of crushing the object)

- The door threshold (During the closing, the sensor should be able to detect the object so as to avoid any contact in the process)

BEA Offers In Tolerated-Risk Environment

The IXIO-D secures the door threshold during closing. (There is an exception where full safety coverage is needed even in a tolerated risk environment. If the distance between the wall and the moving leaf is less than or equal to 20cm, the related side screen must be safe to avoid crushing)

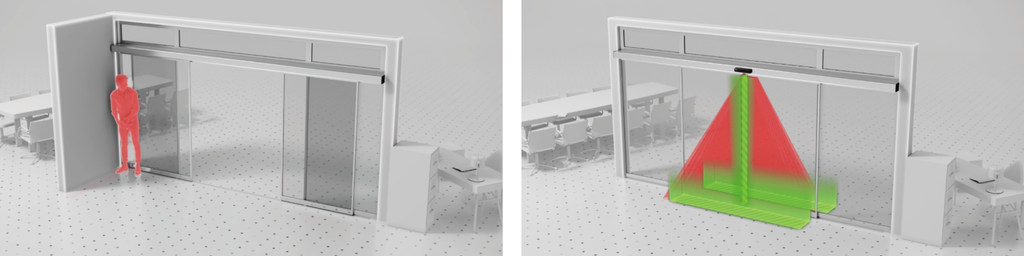

Escape Route Regulation

Moreover, escape route regulation varies from one country to another. Regarding the solution you use and your environment, make sure that the door will open at 80% within 3 seconds after activation.

Make sure to install a certified escape route radar to activate the door. The detection zone in the escape direction shall be not less than 1.5m measured from the centre of the opening width of the doorset and shall cover at least the entire opening width of the doorset. Safety related parts of the control system used for escape route functionality shall comply with EN ISO 13849-1 Performance Level “d”.

Welcome to explore more on opening and safety solutions for sliding doors.