The burgeoning economic growth and rising living standards have precipitated a significant increase in the number of vehicles on the road. Current statistics indicate that the global motor vehicle population has reached approximately 1.446 billion. This surge has led to heightened traffic congestion and escalating traffic safety concerns.

To enhance traffic management on highways, particularly at toll gates, nations are adopting advanced technologies and solutions such as Automated Vehicle Classification (AVC) and Weigh-in-Motion (WIM) systems.

Automated Vehicle Classification at Toll Gates

Automated vehicle classification (AVC) is a pivotal technology within Intelligent Transportation Systems (ITS), designed to streamline traffic flow and management. By accurately classifying and counting various vehicle types—ranging from light vehicles to heavy goods vehicles and motorcycles—AVC ensures toll charges are levied appropriately based on vehicle categories, significantly mitigating congestion at toll gates.

Challenges in Implementing AVC

The AVC challenge lies in the precision of vehicle profiling. This necessitates the collection of accurate, real-time data, the capability to discern a multitude of vehicle types and dimensions, and the reliability of the system under diverse weather conditions. Consequently, there is a pressing need for high-precision sensors that maintain their efficacy across various environment conditions.

Technologies used in AVC and their pros and cons

Cameras and infrared technologies

Traditional sensor technologies, such as cameras and infrared sensors, rely on the physical attributes of vehicles for detection, including size and shape. While these sensors are relatively cost-inexpensive, some can cover extensive areas, and some are straightforward to install, they suffer from limitations in detection accuracy. Ambient lighting and environmental factors like rain, snow, and fog can compromise their performance, leading to inaccuracies in vehicle profiling and measurement. Moreover, these technologies calls for frequent recalibration or sophisticated AI algorithms, which can be labor-intensive and costly.

Laser technology

Laser sensors operate on the Time-of-Flight (ToF) principle, emitting a laser pulse and calculating the time it takes for the reflection to return. This method yields high accuracy and detailed vehicle profiles, including dimensions and speed, even for moving vehicles. Laser sensors are resilient to a variety of weather conditions, including high temperatures, humidity, rain, snow, and fog, and are less prone to false detections—a critical advantage for toll gate applications.

AVC Laser scanner solutions

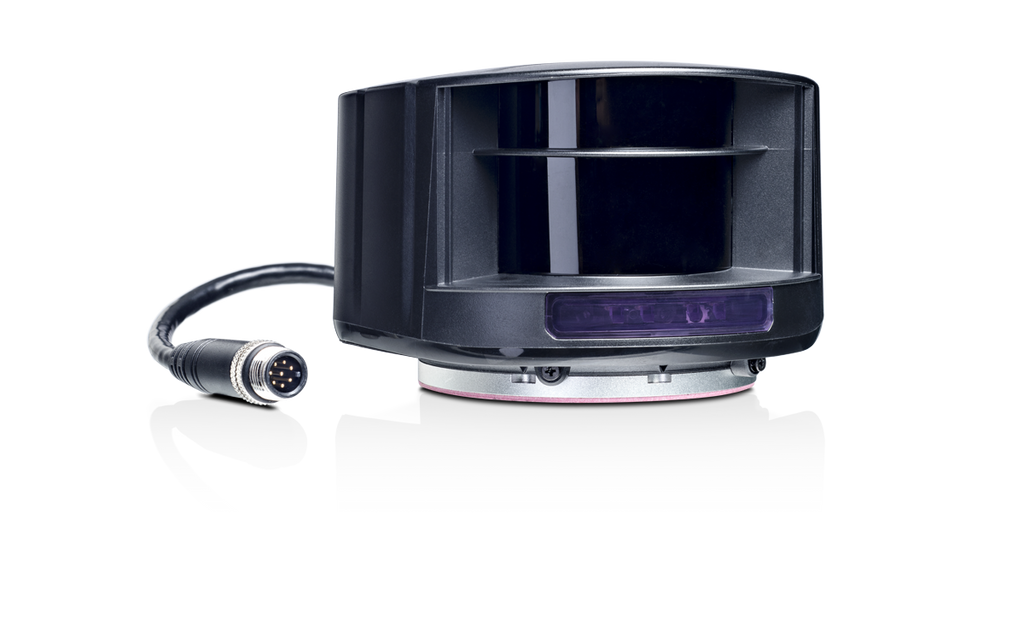

Laser scanners are now widely used in AVC applications. For instance, BEA, a market leader known for its range of laser sensors suitable for AVC, offers the LZR-Raw® U series. These raw data output scanners integrate seamlessly into traffic management systems, enhancing toll collection efficiency and traffic flow with their precise measurements, thereby reducing congestion and bolstering overall road network performance.

Why is LZR-Raw® U chosen in AVC?

- Four or a single laser curtain and selectable frequencies of 15 Hz and 60 Hz, can accurately measure vehicle width, height, and axle count, boasting an accuracy rate of up to 99%.

- The higher amplitude of the laser beam helps to capture accurate measurements for the profiling of the vehicles.

- The robust design (IP65) effectively mitigates the impact of external elements such as sunlight, rain, snow, and stagnant water.

-

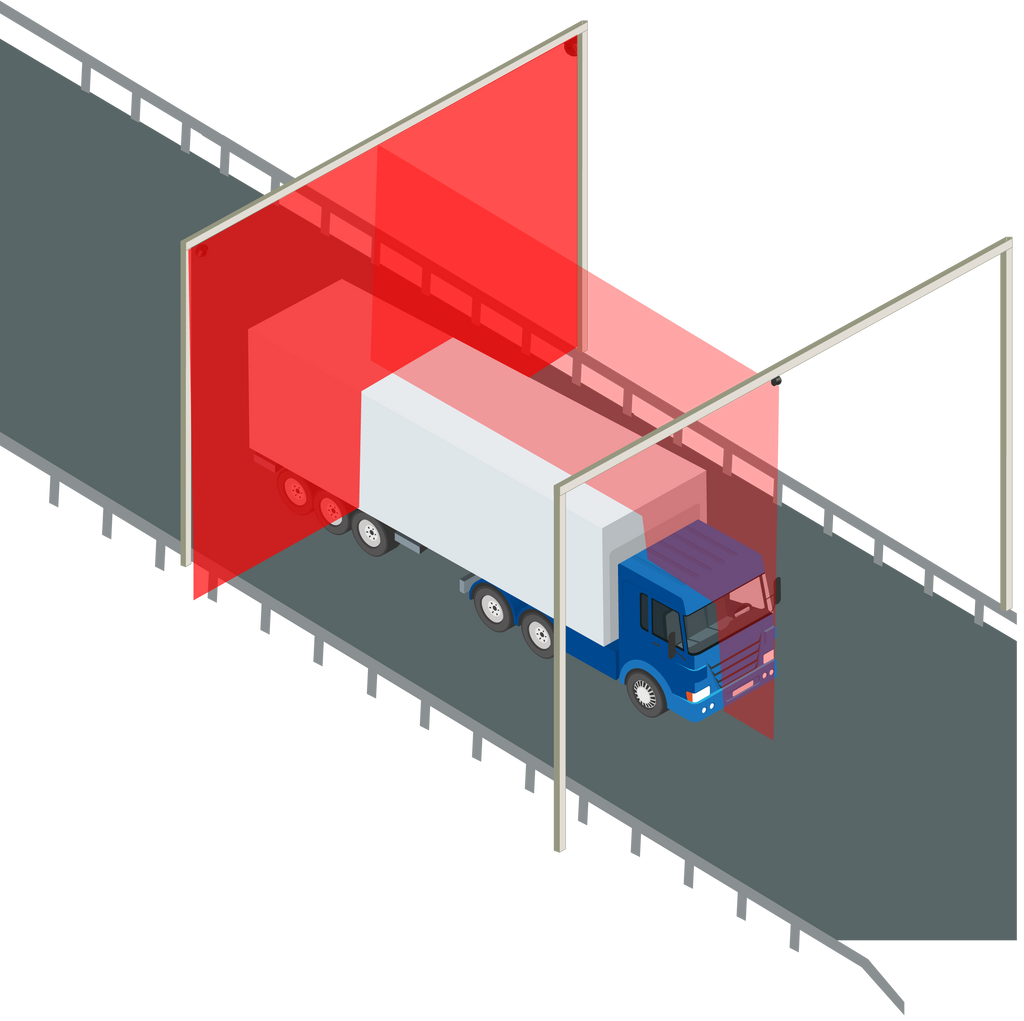

BEA LZR-Raw® U laser scanner used in AVC at the toll gate

BEA LZR-Raw® U laser scanner used in AVC at the toll gate

Weigh-in-Motion at the Toll Gate

Weigh-in-Motion (WIM) is a dynamic weighing system incorporated at highway toll gates to weigh vehicles in real-time without having to stop, ensuring compliance with regulations and alleviating congestion caused by halted vehicles for payment.

The system gathers data through sensors, which is then amplified, converted from analog to digital, and processed to ascertain the vehicle’s weight information, encompassing total weight, axle weight, and the number of axles.

Challenges in WIM application

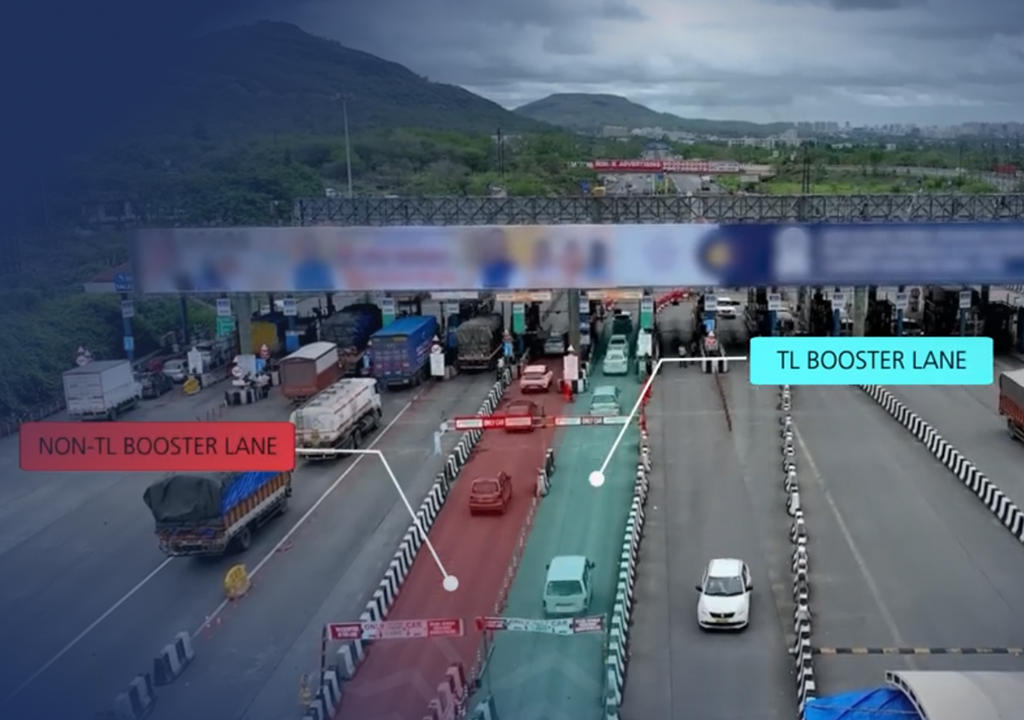

Accurate vehicle weighing is contingent upon an effective vehicle separation system installed at truck weigh-in-motion lanes. This system distinguishes between separate vehicles passing through, preventing inaccurate weighing. Once the vehicle is fully on the weighing platform, the system commences collecting total weight information, enhancing the accuracy of toll station operations and preventing erroneous billing, thus improving operational efficiency, particularly during peak hours when congestion is a significant concern.

Selecting the appropriate vehicle separation solution is (of) paramount importance. The primary vehicle separation solutions available in the market are laser sensors, light curtains, and loop detectors.

Vehicle separation technologies in WIM and their pros and cons

Loop detectors

Loop detectors operate on the principle of electromagnetic induction. It identifies vehicles by sensing changes in magnetic flux as they (containing metal parts) pass through. While cost-effective, their installation requires road disruption, and replacement entails further destruction. Additionally, metallic components of the WIM system can interfere with loop detection, leading to missed detections, and resulting in their gradual replacement by other technologies.

Light curtain

Light curtains detect vehicles through a non-contact linear arrangement of infrared light emission and reception, converting light signals into electrical signals for vehicle data detection. However, their vertical installation results in low environmental adaptability and significant susceptibility to light, weather, and temperature conditions such as fog, rain, and dim night lights. The need for two sensors installed on both sides and the excavation of the ground for connecting communication cables between the transmitter and receiver results in high installation costs and considerable construction and maintenance difficulties.

Laser technology

Laser sensors, operating on the ToF principle, can accurately and swiftly separate vehicles. Compared to light curtain solutions, laser scanners are less affected by environmental factors, particularly strong light, and are less likely to produce false detections. Moreover, the installation and wiring of a single sensor on one side are straightforward and cost-effective.

WIM Laser Vehicle separation solutions

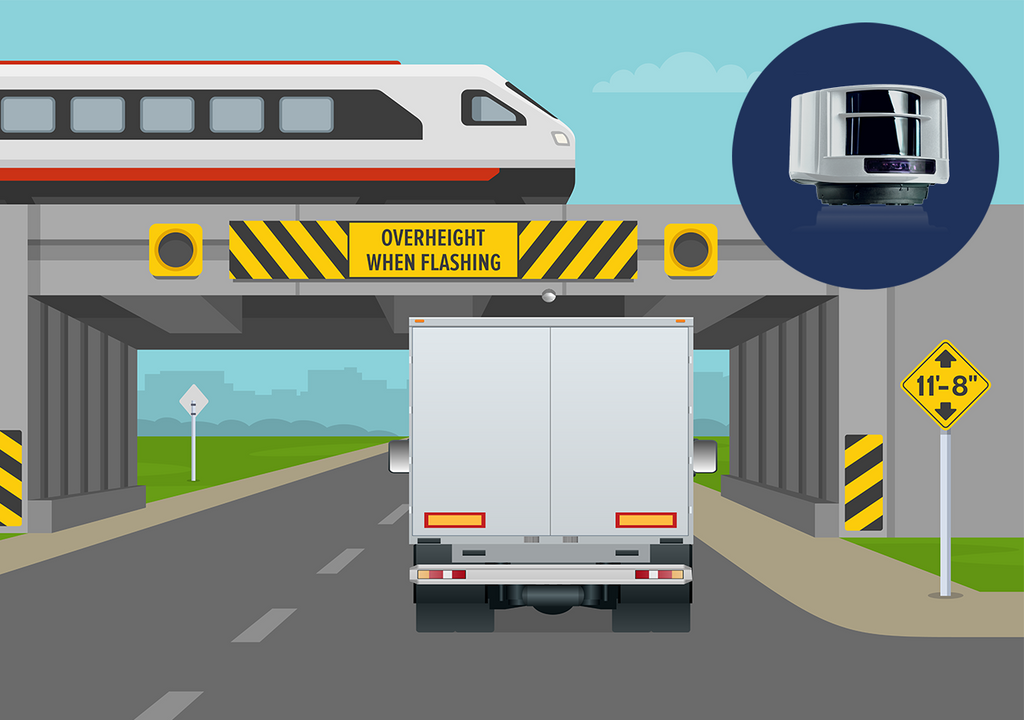

Laser scanners have become prevalent in WIM applications. The BEA FLATSCAN VS305, for instance, is a ToF-based laser scanner with a flat, compact, and self-transceiver design, making it an ideal solution for vehicle separation and anti-tailgating by detecting vehicles passing through toll gates.

Why is LZR-FLATSCAN VS305 chosen in WIM?

- With an angular resolution of up to 0.23°, the FLATSCAN VS305 can accurately and swiftly detect and separate vehicles within gaps of less than 5cm.

- The robust design (IP66) and tilted laser window (after installation) effectively reduce interference from external elements such as sunlight, rain, snow, and stagnant water.

- Only one sensor required on the signal side makes the installation, wiring, and maintenance convenient and cost-effective.

- The compact and flat design facilitates easy installation in confined spaces.

-

BEA FLATSCAN VS 305 laser scanner used in WIM at the toll gate

BEA FLATSCAN VS 305 laser scanner used in WIM at the toll gate