With the acceleration of urbanization and continuous population growth, the subway has become the backbone of urban transportation networks in major global cities, thanks to its significant advantages in efficiency and environmental friendliness. However, the widespread adoption of the subway also conceals safety challenges that cannot be ignored – incidents of passengers accidentally falling onto the tracks on station platforms occur periodically. To address risks and enhance operational efficiency, platform screen doors have emerged, significantly reducing the risk of passengers falling onto the tracks while improving station management. Yet a new problem has emerged: an inevitable gap exists between the train doors and the platform screen doors. This gap can be huge at stations with curved platforms. During peak hours, the danger escalates with heavy passenger flows—clothing, backpacks, and lanyards can trap people in this “hidden trap”. Should the train start moving at that moment, the consequences would be unthinkable.

To mitigate the risks mentioned above, the industry currently employs four categories of protective measures.

| Protective measures | Illustration | Working principle | Feature |

|---|---|---|---|

|

Manual Surveillance |

(Image source: Internet, removed if infringing) |

Relies on visual monitoring of gap areas by station staff, offering certain flexibility during low passenger flow periods. |

Human reliability limitations make it difficult to handle dynamic complex scenarios during peak hours |

|

Anti-pinch baffle |

|

Installed at the lower inner side of platform screen doors (approx. 60cm height × 15cm width). Prevents door closure when obstructed by trapped passenger limbs. |

Existence of protection blind spots;

|

|

Light-curtains |

(Image source: Internet, removed if infringing) |

Laser emitter and receiver arrays installed on both sides of doors (door frame and moving door edge) form multiple parallel infrared beams. |

|

|

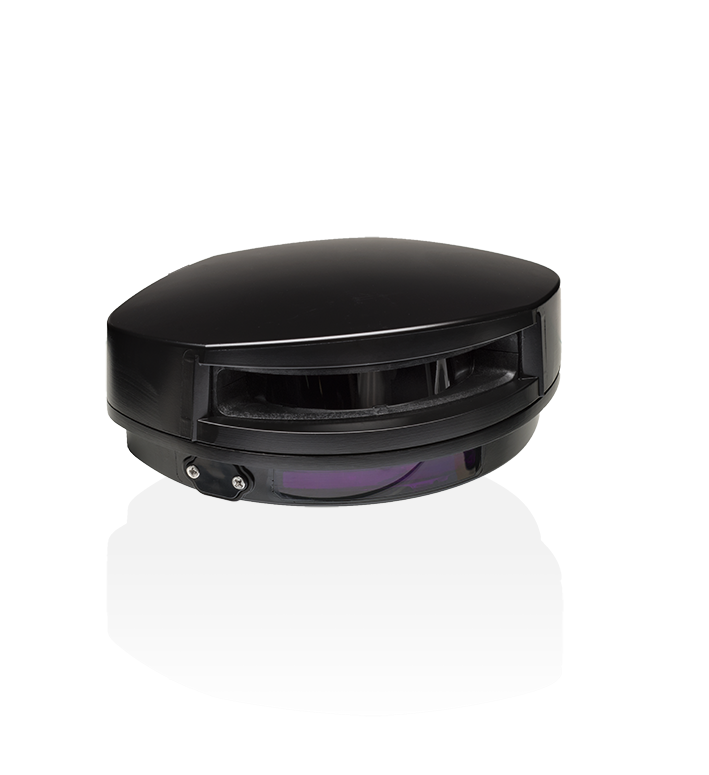

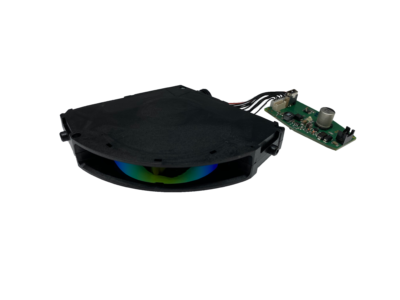

Laser scanner |

|

Mounted on subway platform screen doors, it detects obstacles by projecting laser curtain to scan the gap between the platform screen door and the train body. |

|

Addressing the limitations of existing protective technologies, the BEA-developed LZR Series laser scanners build a robust safety safeguard for metro platform screen door systems through superior performance:

| LZR®- T305 | LZR®- FLATSCAN RS305 | LZR® MICROSCAN U | LZR® FLATSCAN U |

|---|---|---|---|

|

|

|

|

|

|

• Multi-layer Curtain Laser Scanner |

• Single-Layer Light Curtain Compact Laser Scanner |

|

• Single-Layer Light Curtain Compact Laser Scanner |

Core advantages of the LZR Series Laser Scanner

- Single/multi-layer sensors ensure optimal safety protection:

The LZR ultra-thin single-layer sensor adapts to narrow-gap scenarios (e.g., Full-Height Doors in straight platforms), while the LZR multi-layer sensors (adjustable from 1–4 layers) accommodate wider-gap applications (e.g., Half-Height Doors or curved platforms), ensuring optimal safety protection across all environments. - Millisecond-Level Rapid Response:

With an ultra-fast response time of just 20ms – significantly outperforming manual monitoring – the system reliably completes the “detection-alert-braking” cycle before train departure is initiated. This secures critical time for safety. - Exceptional Performance in Harsh Environments:

Utilizing Time-of-Flight (ToF) measurement technology, the LZR maintains robust and reliable operation in rain, snow, fog, and challenging lighting conditions. It overcomes the limitations of traditional light curtains in strong ambient light. - High Protection Ratings:

Certified to IP65 for dust and water resistance and SIL2 for safety, it provides a robust hardware-level protection system suitable for various scenarios, ensuring operational safety. - Streamlined Installation:

Its compact design enables versatile mounting on the left, right, or top of platform screen doors. The LZR integrates effortlessly into both new metro projects and retrofits of existing stations, significantly reducing installation complexity and time in both new and existing systems.

Hong Kong’s East Rail Line – one of the region’s oldest railways – faces unique complexities:

🔹 Accommodates wider Mainland-bound trains

🔹 Curved platforms creating extra-wide gaps

🔹 Making safety protection an extreme challenge!

BEA Sensors deploys 3,150 high-precision laser scanners across the East Rail Line, safeguarding 1,600+ pairs of platform screen doors!

Mr. Brian Chan, Senior Engineer of MTR Corporation Limited, stated in an interview: ‘As a key component of the APG (Automatic Platform Gate) system, the PDS (Passenger Detection System) detects whether passengers are trapped between the APG and train body when metro trains depart. Most platforms on Hong Kong’s East Rail Line are curved and outdoor platforms, making traditional PDS systems unusable. Thanks to the strong immunity capability of BEA 3D laser scanners, the current PDS system on the East Rail Line performs very stably, maintaining normal detection even during heavy rain. Therefore, BEA’s laser scanners can be considered key components in the East Rail Line APG upgrade project.’

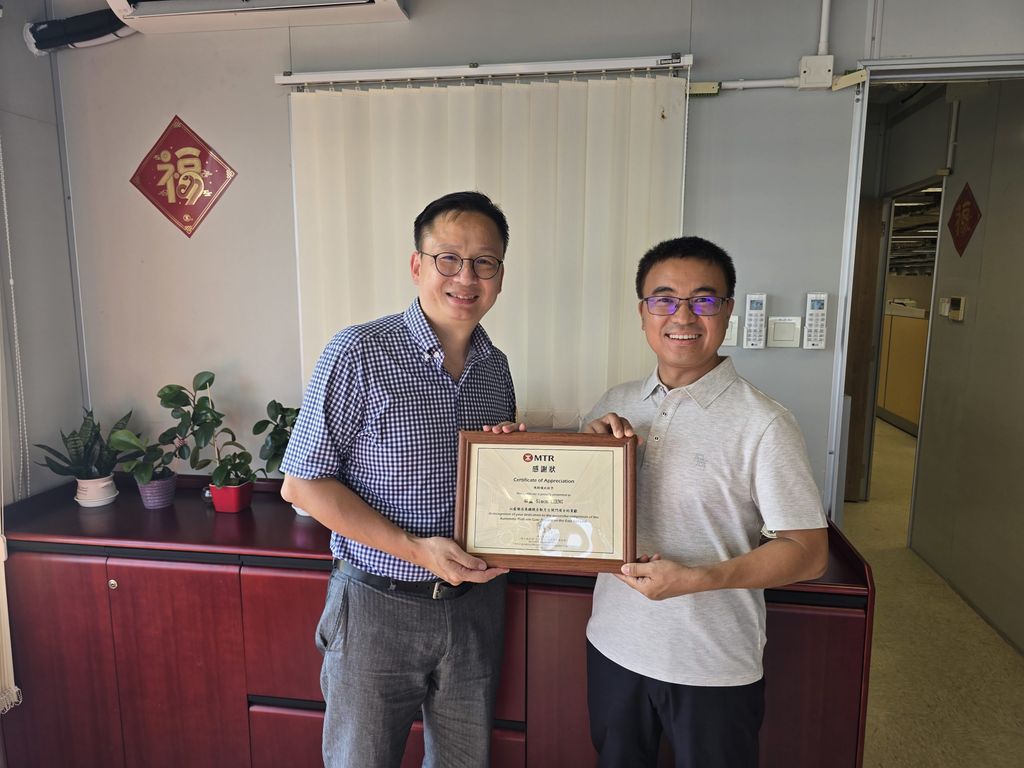

Due to BEA’s outstanding contribution in the East Rail Line platform safety upgrade project, MTR Corporation specially presented BEA with a Certificate of Appreciation. This honor not only highly recognizes BEA’s technical capabilities but also fully affirms MTR’s appreciation for BEA’s role in continuously enhancing Hong Kong metro safety standards.

MTR Hong Kong representative (left) presents Certificate of Appreciation to BEA Sales Director Wayne Chuang (right)

MTR Hong Kong representative (left) presents Certificate of Appreciation to BEA Technical Manager Simon Cheng (right)

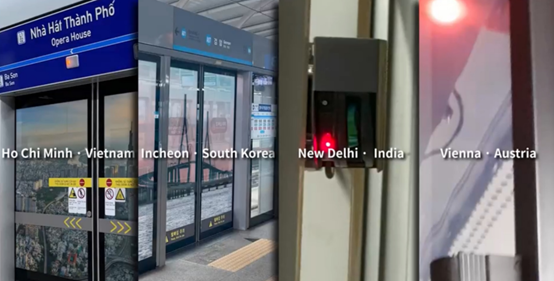

BEA’s unremitting commitment to safety continues to earn profound trust from global partners. Beyond MTR Hong Kong, the engineering effectiveness of BEA’s LZR-series laser scanners has been extensively validated in metro projects across multiple cities worldwide. Their outstanding performance and reliability enable exceptional adaptability and stability even in complex scenarios.

Simon Cheng, Senior Technical Manager for Asia-Pacific at BEA, mentioned that BEA’s sensors are ideal for safety protection projects involving platform screen doors on new metro lines. Additionally, their simple and intuitive installation makes them highly suitable for retrofitting platform screen doors on existing metro lines.

Mr. Wayne Chuang, APAC Sales Director of BEA said that: ‘At BEA, we uphold this mission: to safeguard lives with innovative sensing technologies and build the foundation of a smart society. We are committed to creating a safe and orderly automated world where people everywhere can live with peace of mind. Through LiDAR solutions for platform screen door systems, we protect every safe journey. This not only brings peace to every household but also ensures the smooth operation of urban transportation networks. We continuously drive technological innovation with a forward-looking vision, ensuring safety solutions evolve to meet societal needs. Let us join hands to build a new era where technological innovation not only serves society but proactively protects and empowers our future.