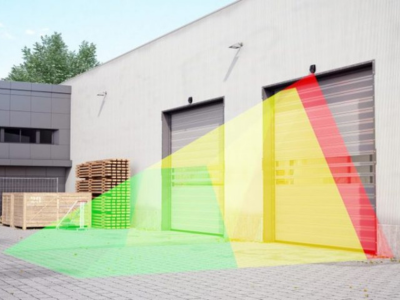

Driven by rapid development of the economy, industries such as manufacturing, logistics and warehousing have witnessed significant growth and demand in efficiency for cargo entrances and exit. The trend towards automation solutions further propels market demand for high-speed automatic doors. These doors typically operate at a speed of over 2 meters per second, improving passage efficiency. However, due to this high operating speed, it also introduces the element of potential safety risks such as crushing, shearing and impact on people or vehicles passing through during the operation of doors.

Any safety protection industry standards for high-speed industrial automatic doors?

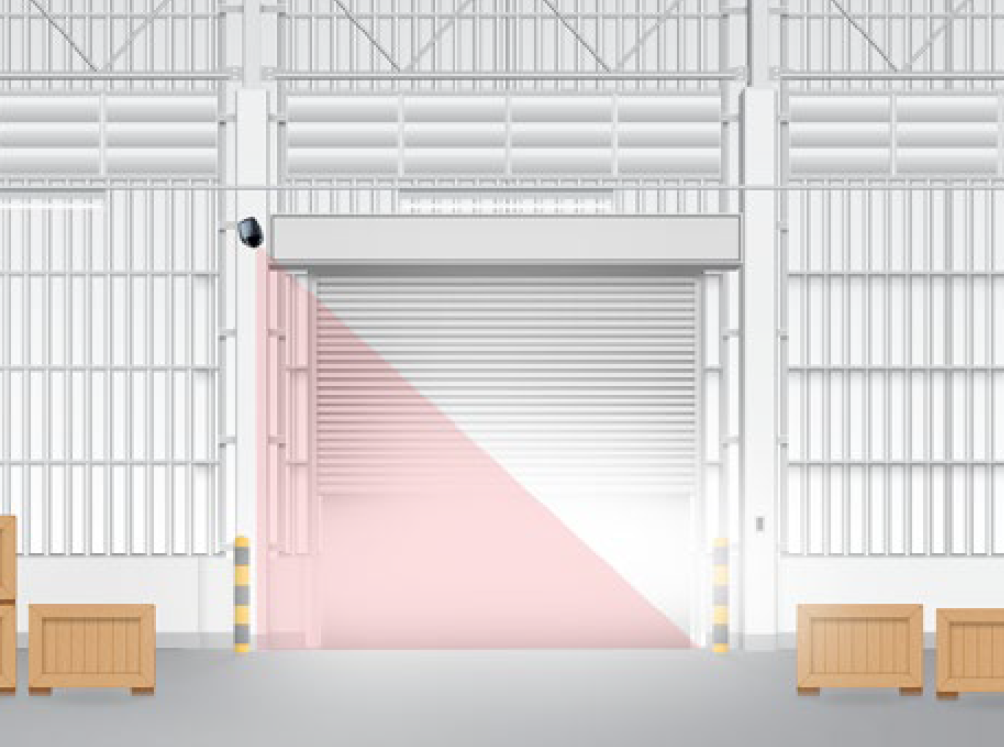

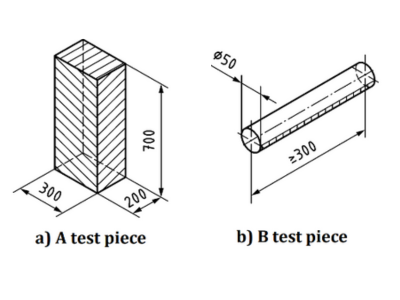

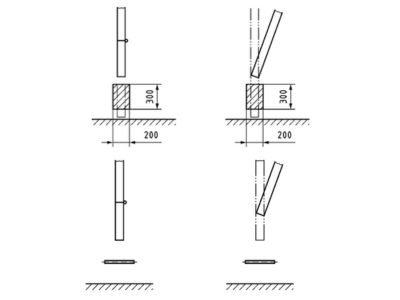

The industry standard clearly defines the safety requirements and test methods for the use of power-operated doors, such as industrial doors, commercial doors, garage doors, and gates. The standard stipulates that high-speed automatic doors must be equipped with effective safety protection measures. It is required that during the opening or closing process of the door, the presence of test piece A or test piece B can be stably detected within the threshold area directly below the door operator (as shown in the figure below), and the automatic door will automatically stop operating or rebound when they are detected.

-

Test Piece A&B

Test Piece A&B -

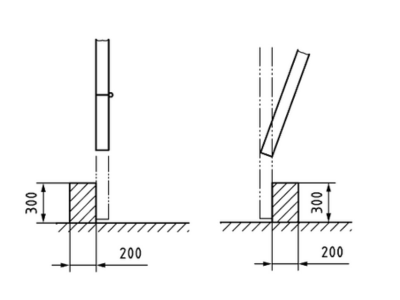

Testing of presence detection active on one side with the A test piece

Testing of presence detection active on one side with the A test piece -

Testing of presence detection active on both sides with the A test piece

Testing of presence detection active on both sides with the A test piece -

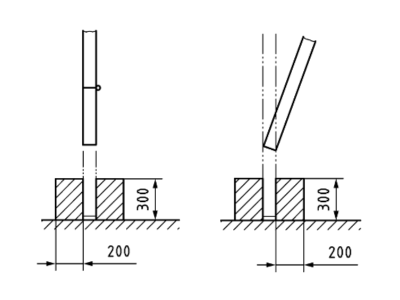

Testing of presence detection active in the door aperture

Testing of presence detection active in the door aperture

Choosing the appropriate sensors to provide safety protection is necessary to ensure the safe operation of high-speed industrial automatic doors.

There are various types of safety sensors used for high-speed industrial automatic doors on the market, among which the most widely used are light grid and laser scanning sensors. So, how do their performances and applications compare, and which is the better choice for the safety protection of high-speed industrial doors?

Light Grid Sensors VS Laser Scanning Sensors

Light Grid Sensors

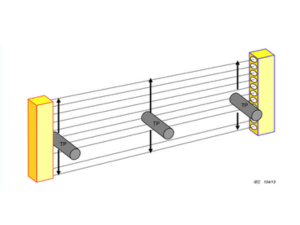

Light grid sensors mainly consist of a transmitter and a receiver, forming an invisible infrared light grid area. When an object or person enters this area, it will block the infrared beam. The receiver senses and sends a signal to the control system, triggering emergency shutdown or other safety response measures. This mechanism ensures that in the automatic door system, once goods or personnel enter a dangerous area, the system can respond quickly to ensure the safety of personnel and equipment.

No doubt light grid sensors have the edge on fast response and non-contact detection, they are however still limited to some specific environments and have risks of false trigger and missed detection, including:

- The light grid is susceptible to interference such as dust, smoke, or intense reflected light, which may result in false triggers.

- In environments with solid electromagnetic fields, light grid may also be subjected to interference, despite not having an object in the detection area, the light grid sensor may still be triggered, resulting in doors being unable to close.

- The protection area is limited as it is only able to cover the area directly below the door operator. The inability to distinguish between different target objects leads to missed detections.

- The light grid sensor is complex to install, debug and maintain.

-

Principles of Light Grid Technology

Principles of Light Grid Technology

Laser Scanning Sensors

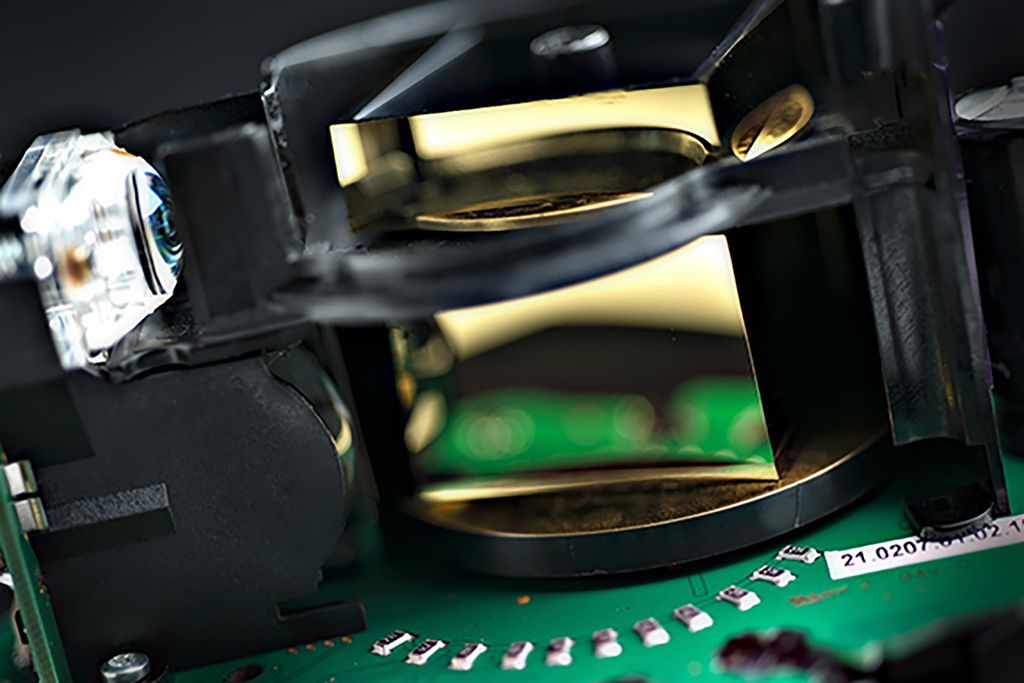

Laser scanning sensors work on the principle of Time of Flight (TOF). The sensor sends out an intense light pulse in a defined direction and then measures the time it takes for the signal to return. Since the speed of light is constant (approximately 300,000 km/s), this time is proportional to the distance between the sensor and the first target encountered by the light pulse. By sending out multiple beams in multiple directions (2D or 3D), the sensor can know the precise location of any target in its detection area at any given time. By analyzing this information in a very short time, it can quickly determine the shape, speed, and direction of any target.

-

Principles of Laser sensors

Principles of Laser sensors

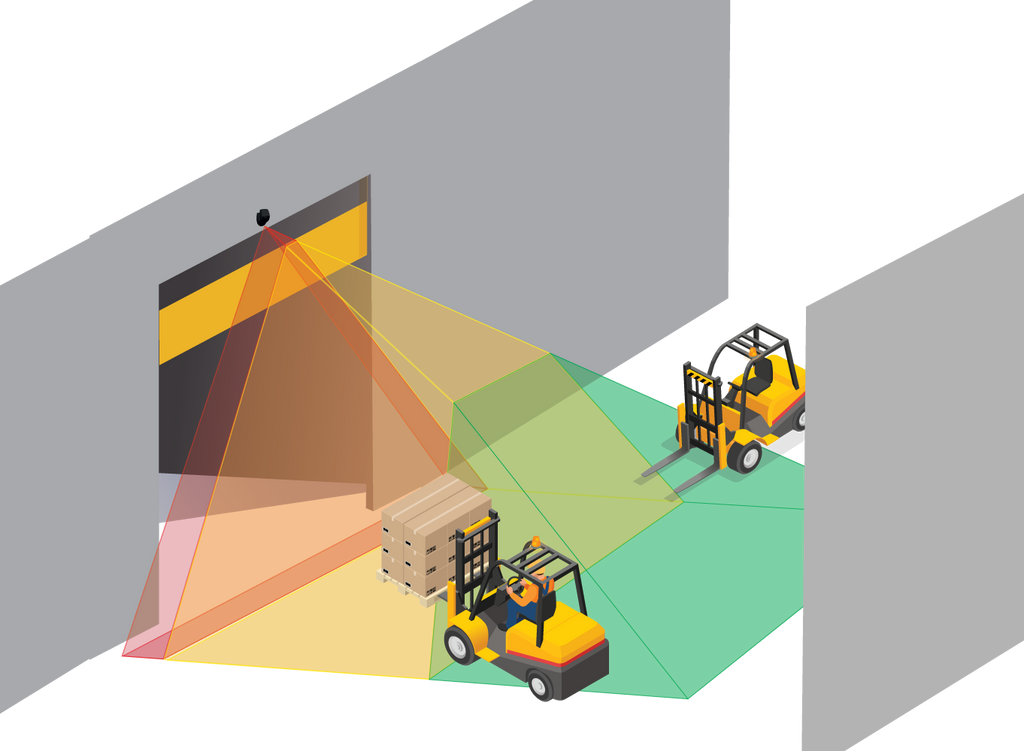

Compared to light grid sensors, not only can laser sensors detect the presence of objects to trigger automatic doors to open, but it is also able to detect the distance and dimension information of target objects. This ensures reliable safety protection while reducing the frequency of door opening and saving energy:

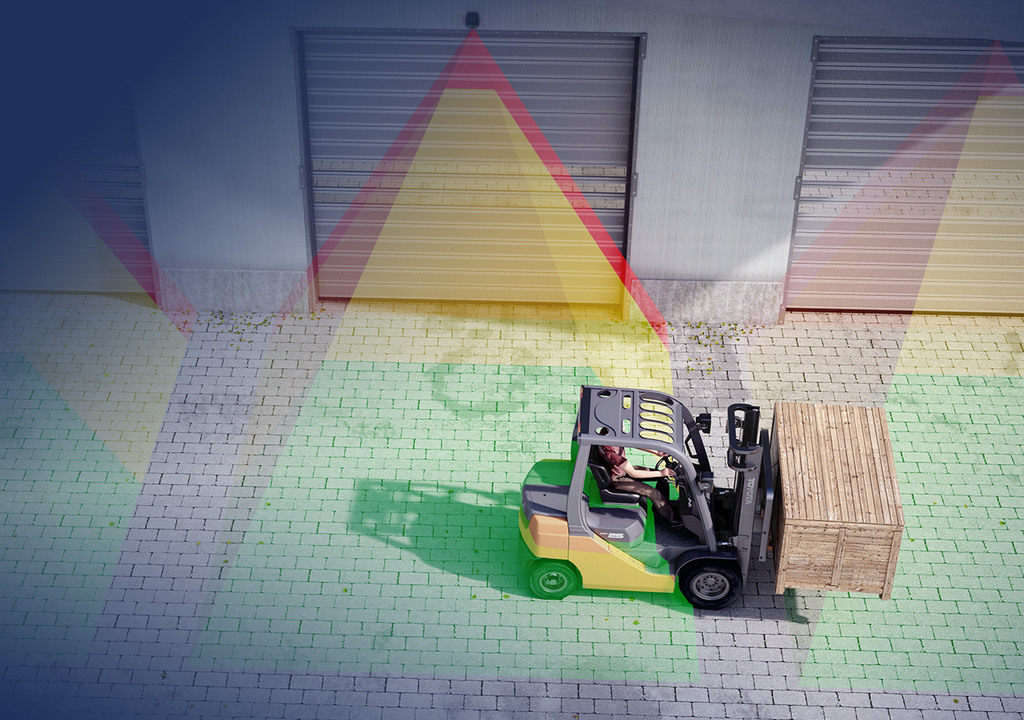

- Safety protection: When the target object is far from the door, the sensor gives an opening signal to open the door. When the target object moves to a specific distance from the door, the sensor provides a protection signal, keeping the door open to protect people or objects passing through.

- Energy efficiency: Laser sensors can detect the size and shape of the target object, thereby classifying and determining the target object. Only when the target object fulfils the defined conditions, the sensor then sends a corresponding signal for the doors to open. Similarly, should the target object not fulfil the set of pre-defined conditions, the sensor does not respond, thus avoiding unnecessary opening of doors. This brings about energy savings and cost efficiency for air-conditioning or heating for users.

Through the above comparison, on the basis of meeting passage efficiency of high-speed doors, laser scanning sensors are superior to light grid sensors not just in detection accuracy, but also possess robust anti-interference capabilities against the external environment, not affected by environmental and lighting conditions. In addition, laser scanning sensors respond quickly, are more convenient to install and maintain, reduce the maintenance and damage to the doors and can also provide diversified functional options, providing more comprehensive safety protection while ensuring passage efficiency.

With an increasing recognition on the benefits of using laser sensors by users, it brings about the rapid rise in integration and adoption of laser sensors on high-speed automatic doors. Below we use an example of the widely used and well received BEA Industrial Door sensor, LZR®-WIDESCAN, to enumerate the advantages of using laser sensors.

Outstanding Industrial Door Laser Sensor Representative: BEA Electronics LZR®-WIDESCAN

The 7-layer laser scanning light curtain of LZR®-WIDESCAN forms a 3D detection area and can define different detection functions throughout the detection area. The presence function detects objects within the area, the motion function detects moving objects within the area, and the safety function can detect objects larger than 25cm, providing all-around three-dimensional safety protection for high-speed industrial doors.

In addition to its excellent detection capabilities and accuracy, WIDESCAN also has the following features:

1. WIDESCAN supports a variety of additional functions to enhance detection accuracy and capabilities.

Virtual Pull cord Function: Allows the door to be opened at a specific position only when needed.

Direction Recognition Function: Detects target objects moving in a specific direction, filtering out objects parallel to the door.

Height Detection Function: Only detecting objects that meet the set height requirements, ensuring objects below the set height are undetected.

Speed Trigger Function: Only detects objects that meet the set movement speed requirements, and objects not meeting the speed requirements will not be detected.

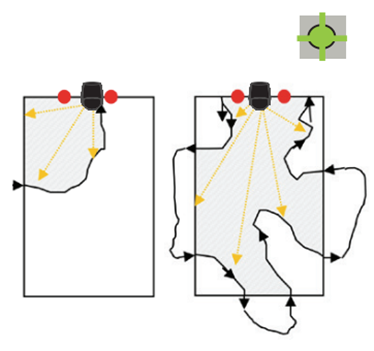

2. Customizable Detection Area Shape

WIDESCAN can customize the actual detection area of the sensor according to user needs through self-learning and supports the setting of “irregular” detection areas.

-

WIDESCAN Detection Area Setting Example

WIDESCAN Detection Area Setting Example

3. Convenient Installation and Calibration

Supported on both IOS and Android platforms, the LZR®-WIDESCAN utilizes a mobile app, making installation and parameter adjustment easy with real-time feedback.

Moreover, as opposed to traditional installation method of light grid sensors, LZR®-WIDESCAN introduces 2 visible spots. This helps users with accurate positioning and angle adjustment of detection fields, making installation and calibration process convenient and fuss-free.

Appendix: WIDESCAN VS a Light Grid Sensor representative

(Highest rating – 5 stars, Lowest rating – 1 star, No star – Feature not available)

| Item | Laser scanner | Light grid |

|---|---|---|

|

Easy to install |

★★★★★ |

★★★ |

|

Easy to adjust |

★★★★★ |

★★ |

|

Accuracy |

★★★★★ |

★★★★ |

|

Function |

★★★★★ |

★★★ |

|

Safety |

★★★★★ |

★★★★ |

|

Safety ahead and beyond the door |

★★★★★ |

|

|

Motion detection |

★★★★★ |

|

|

Presence detection |

★★★★★ |

★★★★★ |

|

Height detection |

★★★★★ |

Comparing the performance of light grid and laser scanning sensors, it is not difficult to see that laser scanning sensors represented by BEA Electronics LZR®-WIDESCAN are undoubtedly a better choice for the safety protection of high-speed industrial automatic doors!