The industrial door market is expected to reach US$ 2,266.2 mil in the year 2025 compared to US$ 1,525.1 in the year 2016. The increase need for industrial doors, need for sustainable solutions, rising energy costs leave unique challenges and opportunities ahead.

Industrial doors comprises of different product ranges such as dock levellers, dock shelters and lifting platforms. However, the role that these doors play in many organisation’s supply chain cannot be understated. Many businesses investing in industrial doors are well aware of their considerable impact on the efficiency and dependability of a firm’s logistics, we here summarise our findings on how adoption of right sensors and door settings can further improve energy saving.

Energy costs have skyrocketed in recent years, and as the current economic situation continues to unsettle, business owners are looking for avenues to remain as efficient as possible. We through this article try to shed light on how industrial doors are continuing to help save energy and boost productivity for warehouses and distribution centers.

The industrial doors that we use at our premises will exert considerable influence on your organisation’s broader energy consumption. Nowadays, an energy saving strategy has wider implications. In our ongoing bid for sustainability, we must all find ways to reduce energy consumption to not strain resources that potentially harm our environment. Energy efficiency is a desirable goal not just for business, but for our entire planet.

During the winter, there is an obvious compulsion to curtail heat loss from a building, this season being one in which businesses consume a greater amount of energy. That, in turn, is not exactly great news for an organisation’s budget, or for minimising its adverse impact on the environment.

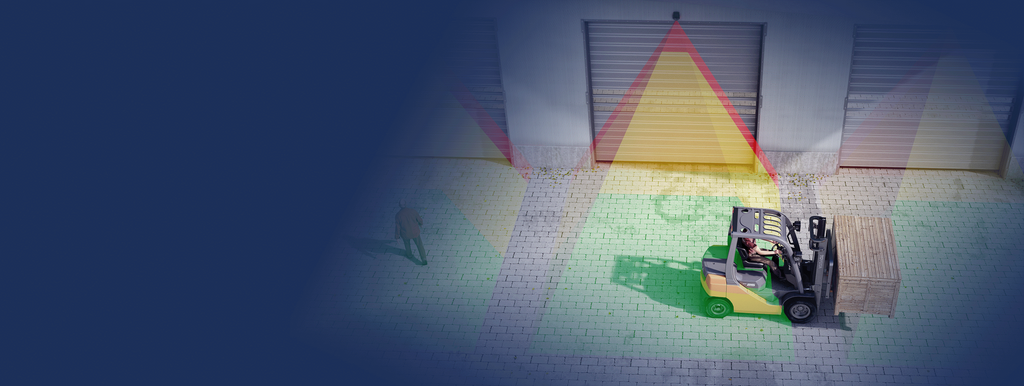

We over the last couple of decades have observed less than 10% of industrial doors use sensors for closing, and use timers instead to close the doors. If the door is set to close too soon, people or objects haven’t moved out of the safe zone, which may lead to potential safety concerns; However if the closing time is set too long, this exerts concerns over increase HVAC losses. The greater the time your doors remain open the exponential the HVAC losses inside your premises. Hence industrial doors solutions mainly focus on providing solutions which are faster to operate at speeds of 2.5m/sec. In such scenario leaving the door open for 15 to 20 seconds by default timing defeats the entire purpose of installing a high speed door.

An industrial door where a sensor is observing its environment and closing it as soon as it sees the target moving out of the safe operation zone closes much fater compared to traditional timers, herewith the energy saved is significantly higher compared to standard timers.

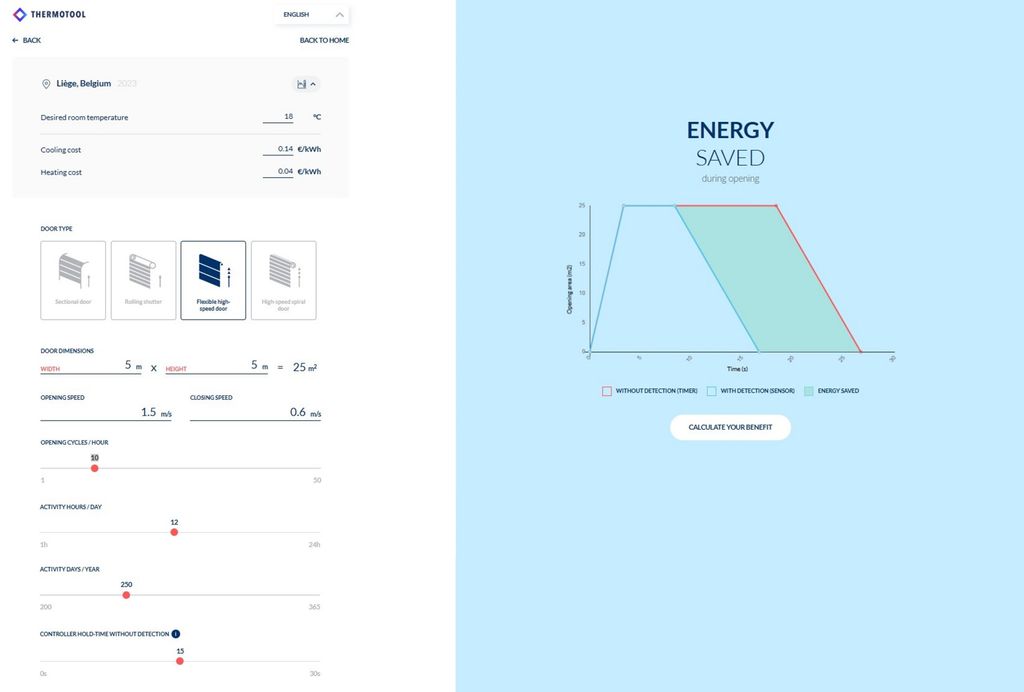

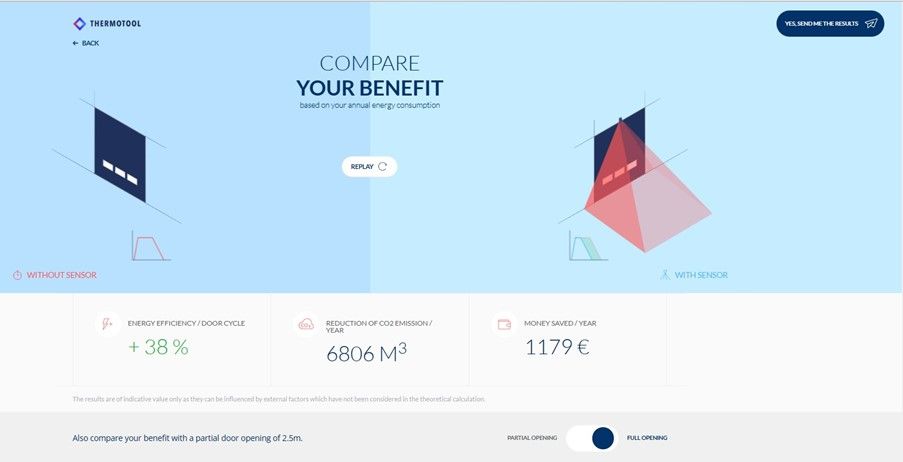

Now lets take a concrete example of a flexible high speed door. Follwing are the assumptiosn on the door operating cycle. Considering the door operating cycles we observe the following savings with respect to energy savings, reduction of CO2 emission and also revenue saved on account of sensor usage. One 5Mx5M automatic door can improve energy efficiency by 38% by using sensors to control its opening and closing time when the running time and the number of opening/closing are the same, reduce carbon dioxide emissions to 6806M³ per year, and save about 1179 euros per year.

Door type, geography, energy costs, door usage and purpose may vary and for your adaptability BEA has developed a professional energy saving calculation tool the thermotool where you can assess the energy saving opportunity of your existing doors or new projects. Do reach out to our sales colleagues to learn more about the tool and the right solutions that will enable you to maximise energy savings on your doors.

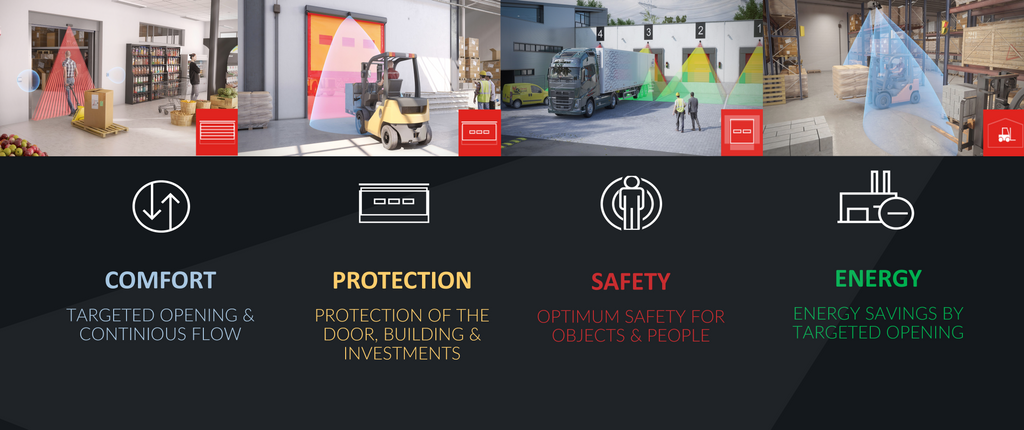

Here at BEA , we design, manufacture and supply energy-saving door sensors for which various options are available to help reduce heat loss. Those options include the likes of reduced opening and closing times, user specific target opening, parallel traffic elimination and optimum safety for people and objects. Feel free to contact our local sales or go to our website to learn more about the technology.